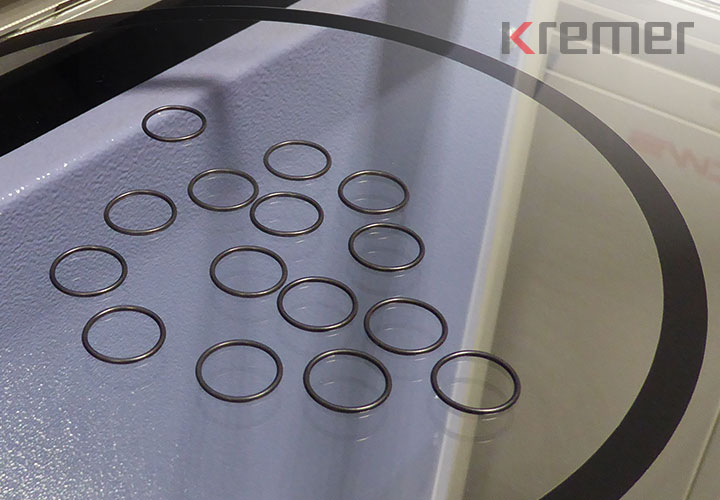

O-rings made of FFKM

FFKM O-rings made from Krevolast®, KREMER's own economical brand

FFKM O-rings made from Krevolast®, KREMER's own economical brand

KREMER supplies FFPM O-rings - also known as FFPM or under the trade name Kalrez ®. For particularly demanding applications in terms of chemical resistance. The O-rings made from the perfluoro rubber Krevolast® are sometimes required to deliver top universal performance, for example:

- Very good resistance to low and very high operating temperatures,

- Particularly high compression and recovery properties (explosion decompression resistance),

- Wide chemical resistance, e.g. acids, alkalis, other aggressive chemicals,

- Fulfilment of high safety and cleanliness requirements

- Resistant to hot water and vapour,

- Good compression set,

- and resistance to media changes.

In short: you need O-rings made from a material that, thanks to its characteristics, functions safely and reliably even when other elastomers reach their limits. O-rings made from the Hochleistungs-Fluorelastomer FFKM fulfil these extremely high requirements.

O-rings made of FFKM-Krevolast®, KREMER's own brand, are therefore primarily used in the chemical process industry, food industry, vacuum technology, semiconductor industry, in refineries, in the production of biofuels or in the cosmetics and pharmaceutical sectors as well as in pumps, drilling tools, valves, reactors or in analysis and laboratory technology.

The outstanding material properties of FFKM Krevolast® O-rings come at a high price, however. In return, the high costs for this special material and its properties reduce the number of production downtime costs incurred for each maintenance job and replacement of prematurely worn O-ring sealing elements. The use of FFKM Krevolast® O-rings is therefore highly economical. If you have particularly high requirements, opt for the FFKM material Krevolast® - a material that is optimised for your application and represents an economically interesting solution for you. Which of ther Krevolast-Werkstofftypen, which are available in hardnesses of 60, 70, 80 and 90 Shore A for order-related processing, is suitable for your application must be determined in a preliminary quotation discussion with you by our technical advisors.

KREMER offers you the expertise to provide you with exactly the right type of material based on your requirements. You can also take advantage of our assistance in the design of the O-rings as early as the development and design phase. Two very useful calculation tools are available online around the clock. One is our digitally supported Einbauberechnung O-Ringe and the other is our Toleranzberechnung O-Ringe.

Existing

-

Shore Range

60 to 90 -

Temperature Range

-15°C to +240°C -

Oil Grease

Feature available -

Petrol

Feature available -

Diesel

Feature available -

Ozone

Feature available -

Weather

Feature available -

Cleanser

Feature available -

Sea Water

Feature available

Optional

-

Extreme Temperature

-40°C to +330°C on request -

Gas

on request -

Food

on request (FDA compliant) -

Steam

on request

FFKM O-rings? Therefore to KREMER!

Three good reasons why you should choose us as your supplier:

Economically clever alternatives for your application

When looking for your supplier for FFKM O-rings, the cost factor plays an important role for you in addition to their expertise and product quality - after all, FFKM compounds are among the most expensive materials. If you are looking for O-rings that are precisely tailored to your application and are economically attractive, FFKM is the right choice

We offer you this smart alternative with our own FFKM brand Krevolast®. An extremely versatile material: depending on the area of application, you can choose from a total of 13 grades, each with specific properties, all of which have excellent resistance to high temperatures and aggressive chemicals in common. The latter varies depending on the application. This means that we can supply you with exactly the right FFKM / Krevolast® O-rings for your application.

You save time in procurement

Fast, transparent and informative quotations are our strength. Time pressure plays a major role for most of our customers, which is why our O-ring experts work efficiently and flexibly - they know that your production and delivery processes must continue to run smoothly.

We at KREMER are prepared for this situation. As soon as you have sent us your enquiry with all the specifications or spoken to our O-ring consultants in person, they will provide you with a customised quote for your FFKM / Krevolast® O-rings within a very short time - usually within 24 hours. Once we have all the detailed information on FFKM O-rings, we can also quote the delivery time.

No compromises on quality

Would you like to have a supplier at your side who responds quickly to your enquiry, provides you with expert advice and can offer you economically interesting FFKM material alternatives such as Krevolast®? Do you know that O-ring quality in particular is a key factor for process reliability and product quality in your company and have clear specifications that your O-ring supplier must fulfil?

We at KREMER make no compromises. In the course of our more than 60 years of company history, we have focussed on suppliers that meet the quality requirements of our customers and ours. That is why we have developed a range of O-ring material variants under our own FFKM brand Krevolast®, the material properties of which are precisely tailored to the specifications of our customers from a wide range of sectors and industries. We are ISO 9001:2015 certified and apply qualitative as well as ecological and ethical standards when selecting our suppliers.

Numbers – Data – Facts

O-rings business unit

Number of O-rings delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Further information on our Krevolast® material types

FFKM O-rings - extremely resistant under extreme conditions

Black, 80 Shore A, high temperature resistant up to +330°C

Temperature range: from -15°C to +330°C (briefly at 340°C)

Properties:

- Low compression set

- outstanding service life in hot water and steam

- Excellent chemical resistance

weitere Informationen

Download Werkstoffdatenblatt

Black, 91 Shore A, high temperature resistant up to +270°C

Temperature range: from -20°C to +270°C (briefly at 300°C)

Properties:

- good compression set

- excellent chemical resistance

weitere Informationen

Download Werkstoffdatenblatt

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.

Hardness measurement - optimised quality management for O-rings

The hardness of O-rings is measured according to Shore A, Micro-Shore or IRHD (International Rubber Hardness Degree). KREMER has decided in favour of laser-based Micro-Shore hardness measurement, as our customers want to see the hardness of the finished O-ring and not the Shore A hardness of the 6 mm thick material test plate documented.

The requirements for the surface structure of O-rings are becoming increasingly demanding. In addition to the miniaturisation of components, the surface structures of O-rings are also subject to increasing functionalisation.

According to DIN 3771, O-rings must be measured without contact and therefore non-destructively. This applies to the dimensions of the O-rings as well as to surface defects.

KREMER uses non-contact, opto-electronic measuring and sorting equipment that provides very precise data and analyses a large number of quality-relevant parameters. Quality control can also be perfectly documented by optical measurement.

The optical-electronic measuring devices guarantee extremely precise measurements and the realisation of a sorting of previously clearly defined characteristics. This is the only way to separate good parts from bad parts with a zero error rate and to fulfil the requirements for PPM rates, e.g. in the automotive supply industry.