EPDM profiles made of Krevolan®

EPDM profiles made of Krevolan® for door, window and facade construction and industry

EPDM profiles made of Krevolan® for door, window and facade construction and industry

The KREMER own brand Krevolan® (EPDM) is characterized by excellent weather and ageing resistance .

Good heat resistance at temperatures from -30 to 120°C and excellent ozone and UV resistance make the tried-and-tested material Krevolan® (EPDM) the most commonly used elastomer for the manufacture of profiles for door, window and facade construction. The very good resistance to cleaning agents complements the high performance of the EPDM material Krevolan®.

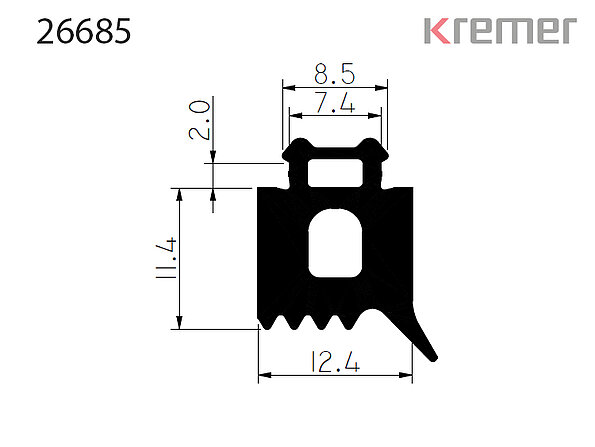

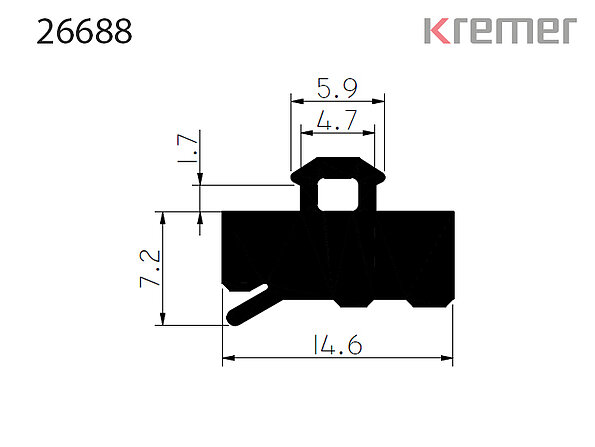

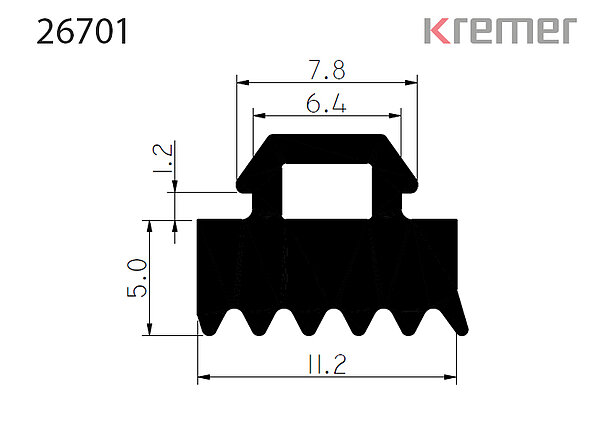

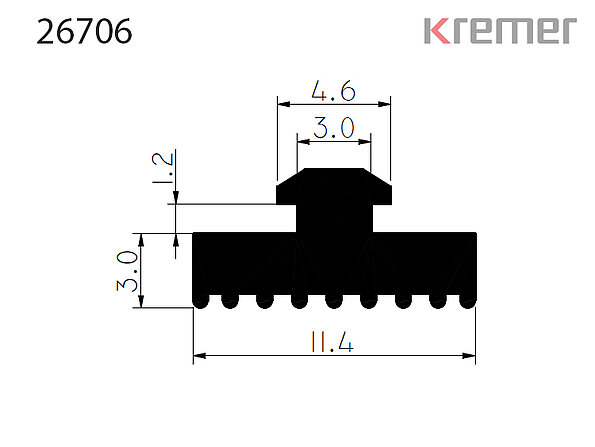

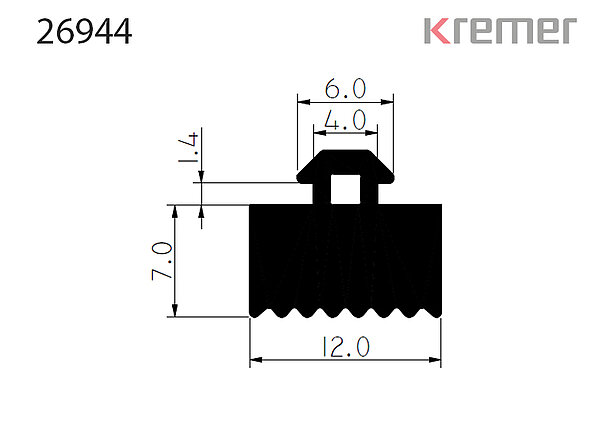

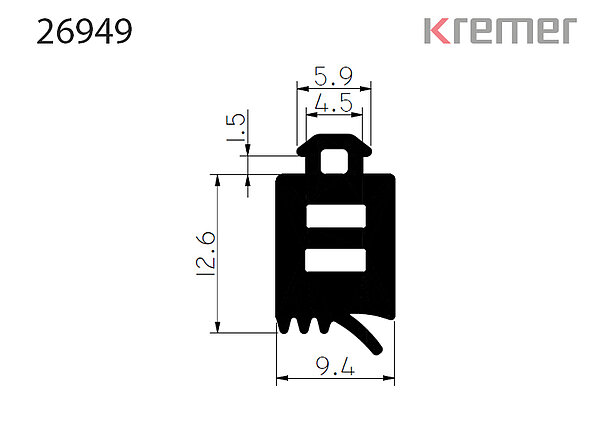

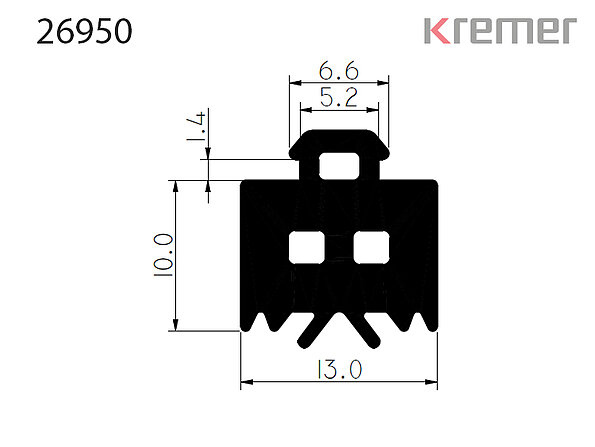

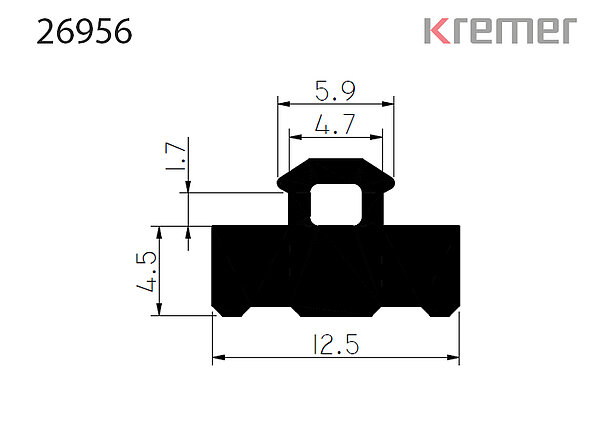

With our Krevolan® EPDM materials, we are able to produce your desired profiles in almost any geometry you require. The material is used, for example, for profiles in greenhouse construction, for the construction of sea containers, in facade construction, door and window construction and, in addition to industrial applications, also in the lighting industry.

Numbers – Data – Facts

Profiles division

Number of profiles delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Anfrage Profile aus Krevolan®

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.

Further information about our Krevolan® material types

Krevolan® profiles for door, window and facade construction and industry

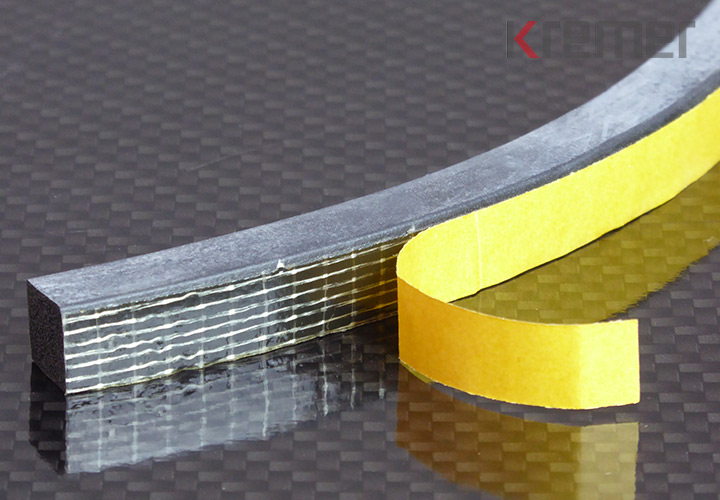

Easy installation with self-adhesive film

Especially when long stretches of profiles have to be fitted, the use of self-adhesive film as an assembly aid is a practical support and simplifies the fixing of the profile during assembly.

Limited storage time

Profile seals that are equipped with self-adhesive film can only be stored for a limited time. Due to the chemical composition of the film, the self-adhesive profile may also have a shorter shelf life. This shelf life is shorter than the warranty period of twelve months for self-adhesive profile seals. Please be sure to follow the storage and processing instructions.

Professional tip: For optimal processing, the profile seals should be stored in an unopened box and processed within six months.

Temperature and processing

- Optimum bonding temperature between 20°C and 30°C in dry rooms.

- Do not process below 10°C .

- Storage temperature at 20°C and approx. 50% relative humidity.

- Make sure the surfaces are clean, dry and, if possible, smooth – this will produce the best results.

- Only remove the protective film immediately before use. This will prevent contamination with dust and moisture, which would impair adhesion.

- It is important that you ensure even and full-surface contact . The contact pressure must be sufficient and even . Both the hands and the processing tools must be free of release agents (especially no oils or grease).

- The profile to be fixed should not hang without support for longer than 30 minutes .

- Please note that if the adhesive joints are subjected to extreme stress, the maximum adhesive strength will only be reached after about 24 hours .

- The profiles should be processed in such a way that permanent stress on the bond is avoided.

Prerequisite for the warranty for self-adhesive products

Self-adhesive profile seals must be processed within six months of delivery, taking into account the storage conditions mentioned above (temperature, humidity and other processing instructions). We cannot accept any liability/warranty for products processed at a later date.

Download product information

Self-adhesive film as an assembly aid - processing instructions