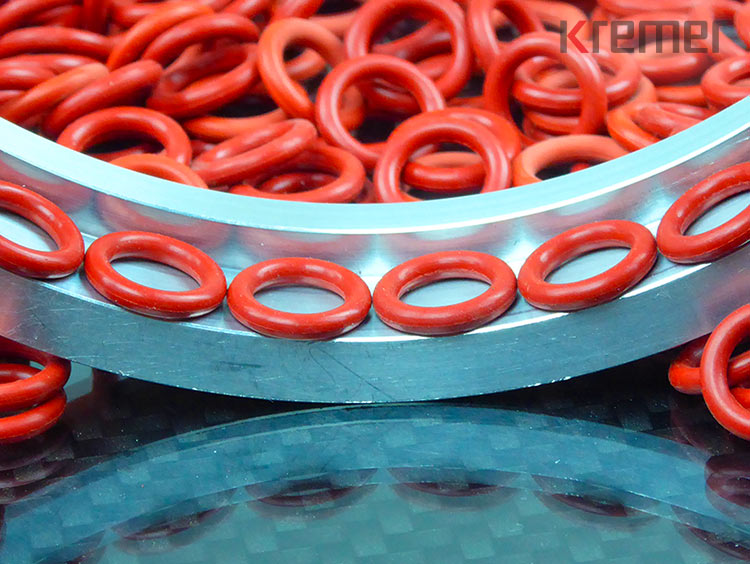

Silicone O-rings: resistant to ozone and weathering

Precisely customised to your specifications

With outstanding properties for static sealing applications or damping elements, silicone O-rings are particularly suitable. Silicone O-rings are also frequently used as electrical insulators. For your application, you have specific expectations of the material properties, such as

- Excellent ozone and weather resistance,

- Excellent temperature resistance in the cold or heat

- Food safe,

- Sterilisability

- Freely colourable LSR silicones

In particular, KREMER also offers silicone O-rings with approvals for use in contact with food (FDA, BfR). As the Anwendungsbeispiele für Silikon-O-Ringe can be very diverse, we need as precise a description as possible of the requirements that the silicone material should fulfil.

The various silicones differ fundamentally in their curing system. They can be peroxidically, bisphenolically or catalytically cured. We also differentiate between high-temperature curing silicones (HTV silicones for short) with their international abbreviation MVQ or VMQ and liquid silicones (LSR silicones for short), whose abbreviation stands for Liquid Silicone Rubber.

Vinegar and room temperature cured silicones, as known from the DIY market, are not part of our delivery portfolio.

KREMER supports you in checking your material preselection with its online tool, with which the chemische Beständigkeiten can be tested against a specific chemical in comparison to the vast majority of elastomer materials.

Our specialist consultants have the expertise to offer the right design based on your requirements profile. You are welcome to take advantage of our assistance with the design of the O-rings as early as the development and design phase. We provide two very useful calculation tools for this purpose - the Einbauberechnung O-Ringe and the Toleranzberechnung O-Ringe.

KREMER actively supports you with the question of how to reduce the high static friction coefficient of silicone O-rings for automated assembly or the stick-slip behaviour for dynamic applications. These issues can be addressed for almost all elastomeric materials by a Beschichtung mit umweltfreundlichen Lacken we must reserve the right to determine the suitability of silicone O-rings for coating by means of tests.

Silicone O-rings for industrial production - therefore to KREMER!

These three reasons will convince you that we are the right supplier for you:

We know your requirements

O-rings are our core business. The KREMER O-ring experts know what they are talking about and will advise you with their in-depth expertise. Experience how quickly you can achieve a cost-effective result with your silicone O-ring requirements and the expertise of our consultants.

Consultancy, design and procurement: this has been KREMER's expertise for more than 60 years. Our customers come from a wide variety of sectors and industries, and so we have become familiar with every conceivable area of application for silicone O-rings. We see ourselves as a partner to our customers who wants to grow together with them. Our technical advisors want to know exactly what your requirements are and ask the right questions. The result: the optimum silicone material - from HTV silicone (MVQ or VMQ) to LSR silicones and fluorosilicone O-rings (MFQ FVMQ) for your application.

We are fast

We know our suppliers and know who can deliver what and in what quality. This enables us to make a preselection in the shortest possible time. You receive our specified offer without a great deal of research effort and time, allowing you to focus on your internal processes.

After receiving your enquiry about silicone O-rings, we will respond within 24 hours on working days. Depending on the specification of your enquiry, we will send you a customised offer. You will also be pleased with the speed of our delivery times. With only a few exceptions, we can deliver the O-rings at short notice.

No compromises in O-ring quality

Quality is our top priority. To ensure that your processes run smoothly, we have clear requirements for the material. If you provide specifications for the approvals, we will of course fulfil them. In short: you have high expectations of the quality of silicone O-rings and value a supplier who also demonstrates this quality awareness - then KREMER is the right partner for you.

Our customers often have seals for very demanding applications; accordingly, we select our suppliers according to very strict quality standards. At KREMER, this goes beyond product quality: both ecological and ethical aspects are taken into account when selecting our suppliers. And with our ISO 9001:2015 certification, we have firmly manifested this quality awareness in our company.

Numbers – Data – Facts

O-rings business unit

Number of O-rings delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

E-cigarettes are an unmissable trend.

In an e-cigarette, it is not the smoke that is inhaled, but the vapour of a liquid consisting of propylene glycol (food additive E 1520), glycerine (food additive E 422), water, food flavourings and, depending on the design/model, nicotine. Most e-cigarettes consist of three main parts: a liquid reservoir, a vaporiser unit and a battery.

The liquid enters the vaporiser unit via a fine steel tube. The liquid vaporises via a small heating coil. The temperatures are comparatively low. They are around 65°C.

Several O-ring dimensions are installed in an e-cigarette, especially in the area of the vaporiser head.

Precise adherence to the tolerance for the cord thickness is particularly important in order to always ensure the same torque forces when screwing together the individual components of the e-cigarette.

Silicone was chosen as the material. Silicone is resistant to water vapour up to 120°C and meets the requirements for materials that come into contact with food.

Hardly any other product is as versatile as an O-Ring. The range of variants is correspondingly large - in terms of size, material, colour, coating and cord thickness. In most applications, the sealing function is the main requirement for O-rings - here we show you two completely different requirements.

The O-ring must be sufficiently elastic to be pulled over the soother. As it is used close to the child's mouth, food compatibility is essential. The material was selected in such a way that it guarantees a high degree of elasticity on the one hand and does not "wear out", i.e. lose its retaining function, on the other. The O-ring must not tear. Accordingly, the O-ring cord must have a certain thickness so that it can withstand the forces exerted by the child.

Soothers are subject to a DIN standard, so there was a clear size specification. By sending a few samples and calculating the tensile forces, the optimum size was determined together with the customer.

Ultimately, the only material that came into question was Silikon as this is the only way to achieve the transparent colour and guarantee a quality suitable for babies.

Children need exercise. Toddlers like to move around and balance bikes are a favourite with parents. For a children's balance bike, a rubber ring is needed that can be pulled over the wooden wheels of the balance bike. The functionality must not be restricted under any circumstances. Children use the small balance bike in the living room, kitchen and hallway. Of course, the floor should not be damaged. There should be no scratch marks that would tell of the child's first attempts at mobility years later. Desired colour: raspberry red.

The rubber ring needs stability to prevent it from being compressed and the "rolling function" should be guaranteed. There was a clear RAL specification for the colour of the O-ring: raspberry red. A material is therefore required that can be dyed in the RAL colours.

The ring must be smooth and firm to avoid scratch marks and ensure that it can roll. A silicone O-ring is also chosen here. Firstly to be able to supply the desired colour and secondly to guarantee food quality. This is an absolute must for toys for babies and toddlers.

The production of the O-ring in 80 Shore A fulfils the special strength requirements.

The founders of the free-spee GbR tested their new paragliders en route in the Alps. For some time now, paragliders have been technically sophisticated, very lightweight flying machines with which aviation enthusiasts can fulfil their dream of easy flying. During the tests, one detail in the design of the equipment was not to our liking. At that time there was no way to easily adjust the foot accelerator, the accelerator pedal of the paraglider, especially during the flight.

The accelerator is used to increase the flying speed of a paraglider, which is approx. 35 km/h, to approx. 45 km/h if required. By pressing the accelerator pedal, the canopy of the paraglider is tilted slightly forwards, which leads to an increase in speed.

After some deliberation and severalPrototypen finally, a functioning model of an accelerator was created. A utility model is registered at the patent office.

The product design is developed by the office SUBRAUMSTUDIO, which belongs to one of the company founders. The core of the product is a clamping mechanism that connects two lines coupled to the umbrella. The clamping mechanism is supported by a grey silicone O-ring, 10 x 2.5 mm and 65 Shore A hardness from KREMER.

In addition, the silicone O-ring makes for a characteristically simple, understandable and easy-to-maintain design. The O-ring creates the necessary pre-tension for the clamping mechanism, as can be seen in the photos.

The silicone O-ring fulfils the necessary requirements in terms of elasticity and, above all, weather resistance. An outdoor weathering test of the accelerator, which has been ongoing since 2009, impressively demonstrates that it still functions perfectly.

The free-spee accelerator has been on the market since 2009 and is now used thousands of times - 15,000 times to be precise - in the air worldwide.

Product used: O-ring 10 x 2.5, silicone grey, hardness 60 +/-5 Shore A

Product design: SUBRAUMSTUDIO Industriedesign - Dipl.-Ing.(FH) Architektur Andreas Raphael– www.subraumstudio.com

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.