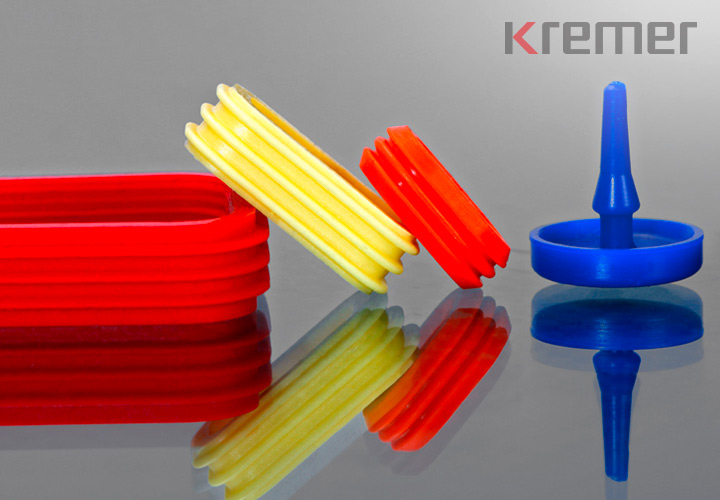

Customised seals

Have your seals manufactured by KREMER according to your drawings or samples

Every detail counts in your production – especially where hardly anyone looks: at the sealing points. Whether a seal works reliably or not depends on subtle details – in the material, the dimensions or even the correct approval.

Standard solutions for seals quickly reach their limits. For example, when aggressive media restrict the choice of materials, temperatures from –40°C to +200°C have to be covered, when installation spaces are limited or approvals such as FDA, DVGW or USP Class VI have to be met.

As a technical purchaser, design engineer or technician, you know that If the dimensions, materials and standards of seals do not match exactly, expensive defects, downtime or rework are inevitable. That is why it is not enough for you to procure ‘just any’ seal – you need one that is individually tailored to your requirements right from the start.

Specific applications require customised seals

There is a suitable seal for every specific requirement. And that is exactly what we manufacture for you at KREMER – according to your drawings or samples. Above all, we consider the decisive factors right from the start so that your seal is perfectly tailored to its intended use.

What we offer:

EPDM seals

FFKM/Krevolast® seals

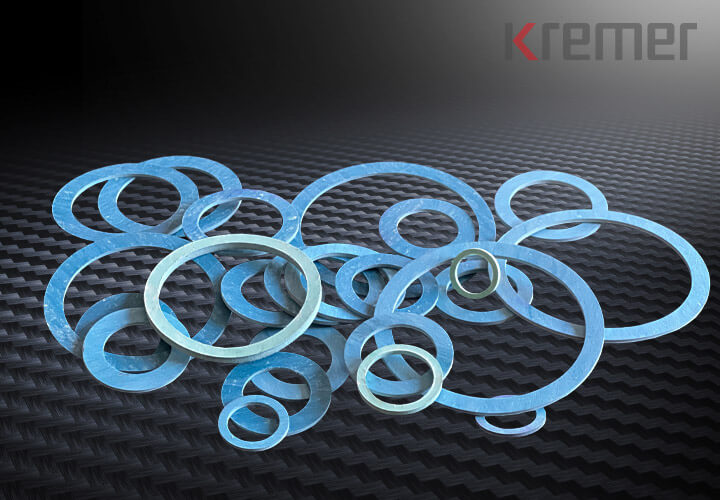

Flat seals

NBR seals

Profile seals

Silicone seals

Water jet cut seals

In addition, we manufacture dimensionally accurate hose rings in our own production facility – and process seals made from other materials such as CR and FKM/FPM.

Your seal fits – because we understand what your application requires

Every industry, every application and every environment puts seals to the test. In the food and beverage industry, for example, there are high requirements for hygiene, temperature ranges and material compatibility, e.g. according to FDA or EU 1935/2004. In contrast, the fuel, hydrogen and chemical industries focus on absolute reliability and safety in order to prevent failures, leaks and environmental risks.

To ensure that your custom-made seals function reliably, you expect your supplier to understand your application or to assist you in selecting the right product if necessary.

That is why we at KREMER think ahead right from the start:

- What media will the seal be exposed to?

- What temperatures and pressures must it withstand?

- What standards and approvals are required?

Questions like these and many others arise in every sealing application – and we have been finding the right answers for over 60 years. For companies in every conceivable sector and industry. This is exactly how we support you when it comes to customised seals that work perfectly right from the start. Because one thing is certain: nothing can replace genuine, personal advice on an equal footing.

Take the safe route with customised seals

Your seal fits perfectly, your processes run smoothly and efficiently – and you can be sure that your requirements are being met precisely from the very start. Let's talk about what your seal needs to do to ensure your processes, product quality and production targets. Our team is just an email or phone call away!

Customised seals: That's why KREMER

Three good reasons why we are the ideal supplier of customised seals for you

Your seal should secure processes, prevent failures and guarantee quality. That's why we develop solutions that are precisely tailored to the shape, material and function – based on drawings, samples or ideas. Right from the start, you will be talking to experts who understand your requirements. We are also happy to support you at an early stage of product development – for example, with rapid prototyping.

When time is of the essence, every hour counts. That's why we keep things short: you speak directly to our expert advisors – no waiting on hold, no ticket system. Once we have received your specifications, you will usually receive a precise response or a concrete offer within 48 hours. For maximum planning reliability in your production.

Customised seals with special dimensions or special geometries require even greater reliability and precision. That is why at KREMER, we tailor materials, production and tolerances precisely to your requirements – documented, tested and traceable. From FDA-compliant materials to DVGW and USP Class VI approvals.

Numbers – Data – Facts

Seals division

Number of seals delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Customised seals: request expert advice now!

Are you looking for technical advice and would like to discuss your customised seals based on drawings or samples in detail with our experts?

Use one of the contact options below and get in touch with your personal contact person directly! We look forward to receiving your enquiry!

Contact

Request advice now!

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.

It all depends on the dimensions!

The KREMER calculation programmes allow you to calculate the parameters of your application quickly and precisely. Because O-rings, moulded parts or rubber profiles can only function optimally if the dimensions are correct. With just a few clicks, you can carry out installation and tolerance calculations with the KREMER calculation programmes.

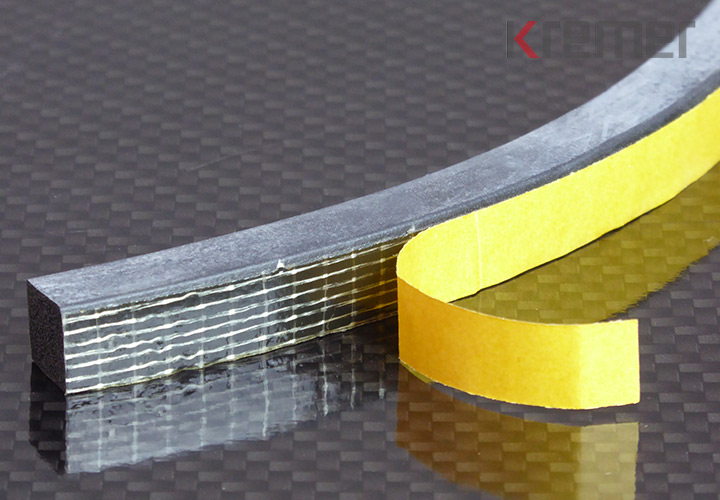

The use of self-adhesive film for elastomer products can be helpful for the user for several reasons. Self-adhesive gaskets are used, for example, for overhead installation of a gasket or to prevent loss during transport of pre-assembled components.

When gaskets, especially profile gaskets with self-adhesive film, are used as an assembly aid for installation, this means that the self-adhesive film has no influence on the function of the gasket after installation.

Self-adhesive stamped gaskets on film are a convenient solution that makes installation easier and safer. If the adhesive film is to have a function other than that of a self-adhesive film for installation purposes, this must be explicitly stated in the enquiry. Our product advisors will carefully check the information on the intended use and include it in the offer according to the possibilities.

In addition to the proper processing and handling of the self-adhesive film in the seal manufacturer's production facility, the storage of the finished elastomer products at the customer's premises plays a decisive role in the durability of the self-adhesive elastomer and silicone products.

The right processing

- Ensure sufficient and even contact pressure.

- Processing tools (including hands) must be free of release agent.

- In the case of extreme loads on bonded joints, it should be noted that the maximum adhesive strength is only reached after approx. 24 hours.

- Avoid permanent tension on the bond.

Underground:

- Do not apply to surfaces containing silicones, paraffins or waxes.

- Do not use paints with adhesion-reducing additives.

- Ensure freedom from dust.

- Ensure freedom from plasticisers.

- Ensure dry surfaces.

- Cover as smooth, closed surfaces as possible.

- Exclude chemical reactions of the surfaces.

Temperatur:

- The optimum bonding temperature is between 20 and 30°C in dry rooms.

- If possible, do not work below 10°C.

- Storage temperature at 18°C and approx. 55% relative humidity.

Influences that impair the adhesive strength of the self-adhesive film:

- High humidity, grease, oil, dust and/or dirt on the surfaces of the parts to be bonded.

- Plasticiser migration.

- Improper storage (deviating from DIN 7716).

Storage and shelf life

In principle, the following applies self-adhesive Seals only a limited shelf life can be assumed. It is possible that the shelf life of the film is shorter than the warranty period of 12 months for self-adhesive products. It is therefore particularly important that the Storage and processing instructions are complied with. We recommend, the self-adhesive products within six months to process.

Warranty conditions "Self-adhesive products"

The product must be processed within six months of delivery, taking into account the above-mentioned storage temperature, humidity and processing instructions. No liability/warranty can be accepted for products processed at a later date.

Download product information

Sheet goods, blanks and flat and flange gaskets made from sheet material, that fulfil tolerance class P1 (fine) place higher requirements on

- the dimensional accuracy,

- the surface finish and

- precision.

Compliance with tolerance class P1 is associated with higher costs compared to P2 or P3. Please allow more budget for tolerance class P1.

For the vast majority of technical applications, the Compliance with tolerance class P2 (medium) sufficient. Sheet goods, blanks and flat gaskets made from sheet material, The products, which correspond to tolerance class P2 (medium), fulfil standard commercial requirements for precision and dimensional accuracy.

Suitable for all applications where dimensional accuracy is not so important. This tolerance class is used almost exclusively for Plattendicke or the Thickness of sheets and rolls Application.

It is applied to Sheet material, blanksand Flat gaskets made from sheet material, that correspond to tolerance class P3 (coarse). There are no special requirements in terms of precision and dimensional accuracy.