Rubber profiles

Profiles made of EPDM, silicone or foam rubber – precisely tailored to your application

EPDM, foam rubber and silicone profiles for industry – where fit, resilience and long-term functionality count

Whether in guides, on frames or on sealing lines – profiles perform key tasks. They protect, they seal, they guide components into position. And if they don't, things can go seriously wrong: Tolerances are not met, media penetrate, components wear out faster than planned.

Many technical purchasers, developers and maintenance engineers are familiar with this problem: the rubber profile looks right on paper. But it sticks, doesn't fit properly or has play where there shouldn't be any. Then it has to be reworked, corrected, discarded – and suddenly the project is at a standstill.

What's more, not every medium is harmless. Not every temperature is stable. And not every environment forgives design compromises. As the person responsible, you don't want a rough solution – you want profiles that work perfectly right from the start.

Custom-made rubber profiles – precisely manufactured for complex geometries, difficult installation spaces and special requirements

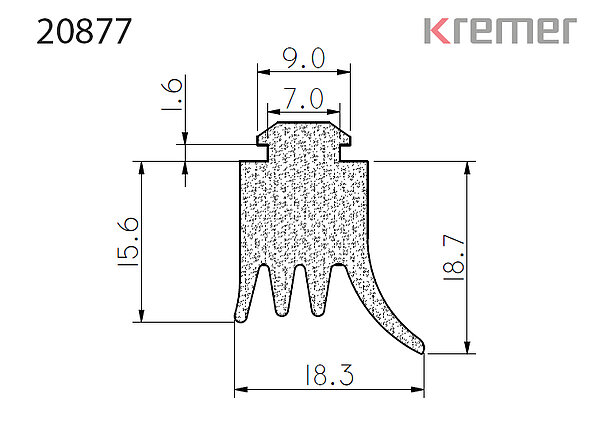

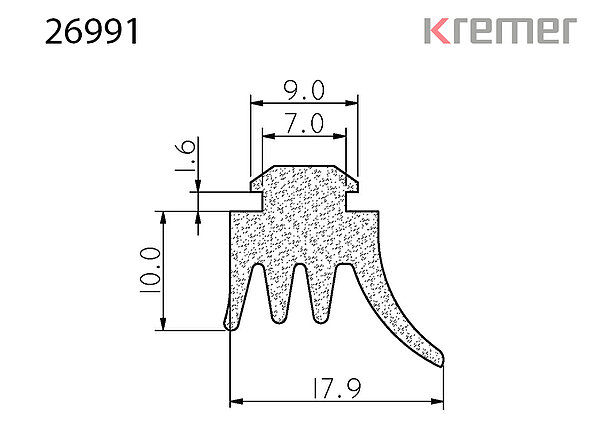

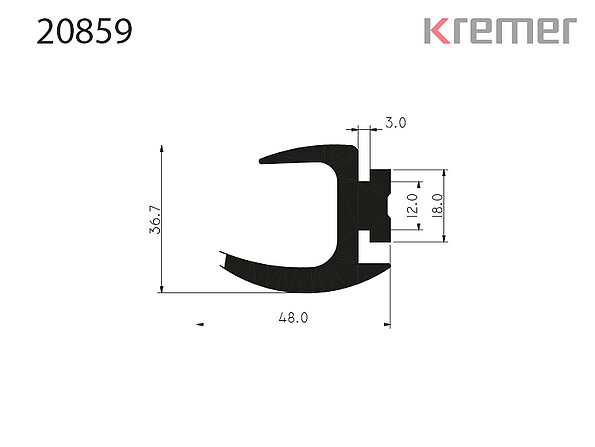

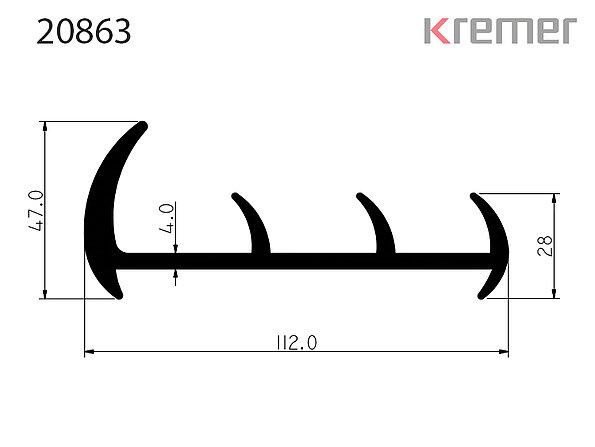

At KREMER, you get technically sophisticated, custom-made rubber profiles that fit precisely into your design – whether as solid or foam rubber profiles made of EPDM or Krevolan® or as solid or cellular profiles made of silicone or Krevosil®.

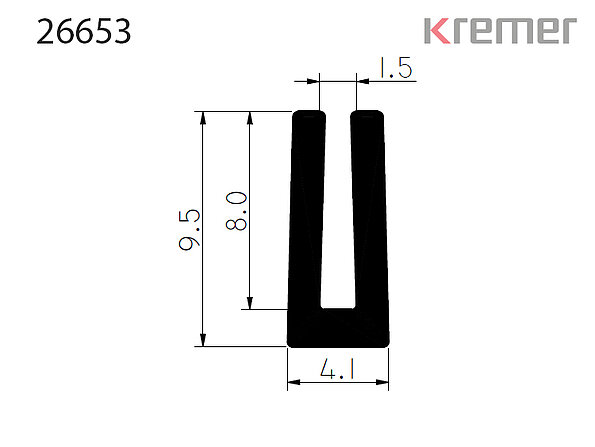

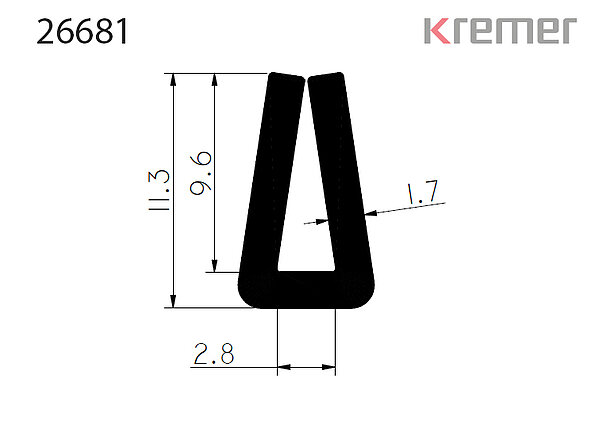

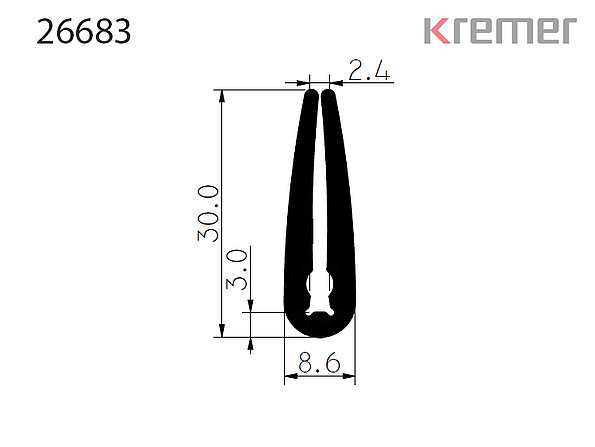

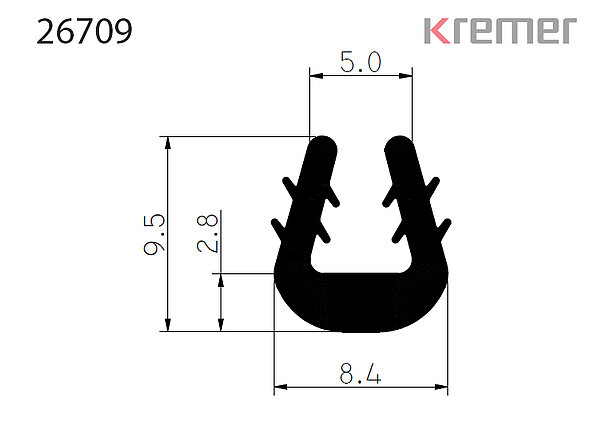

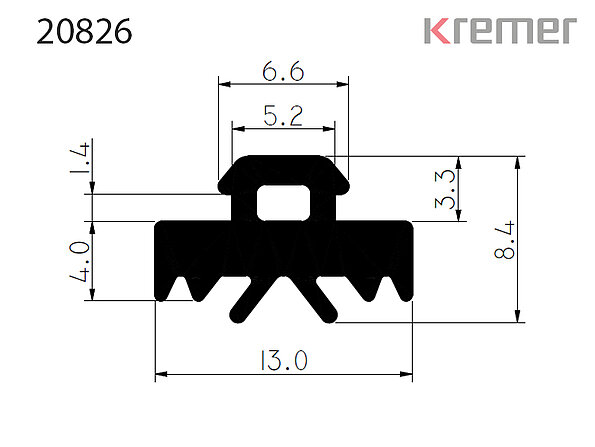

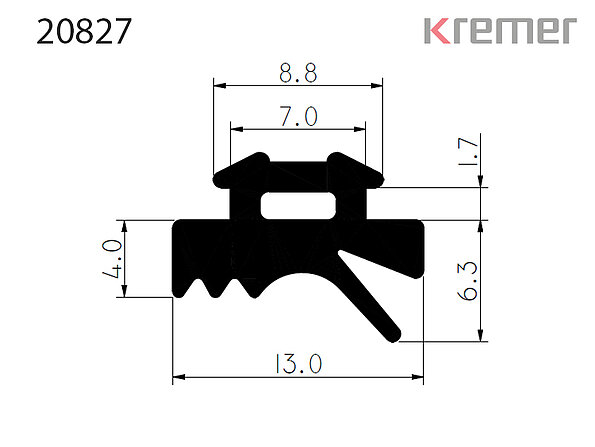

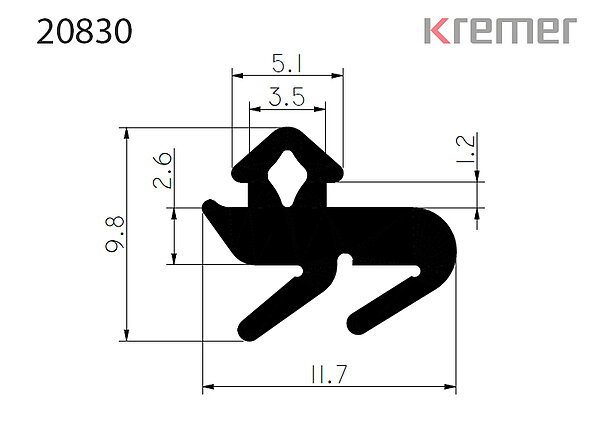

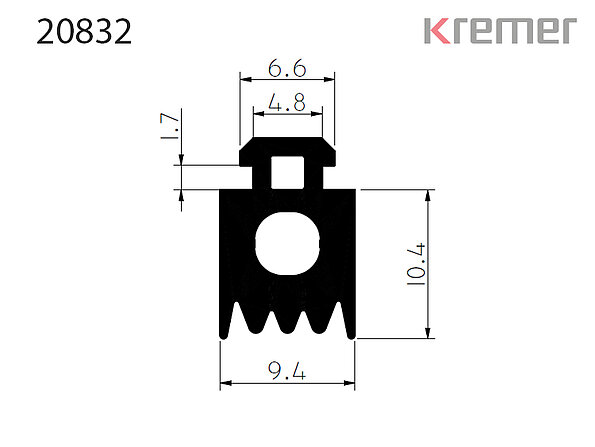

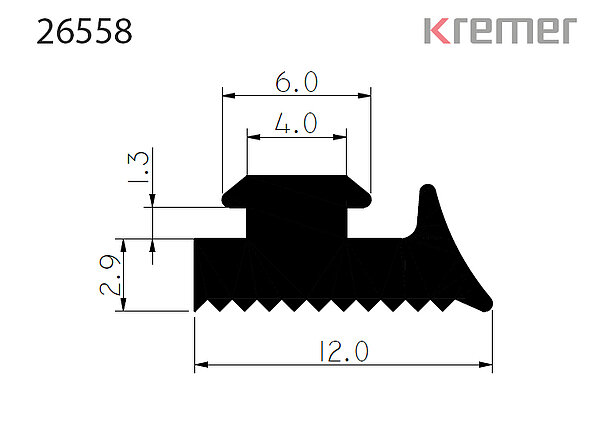

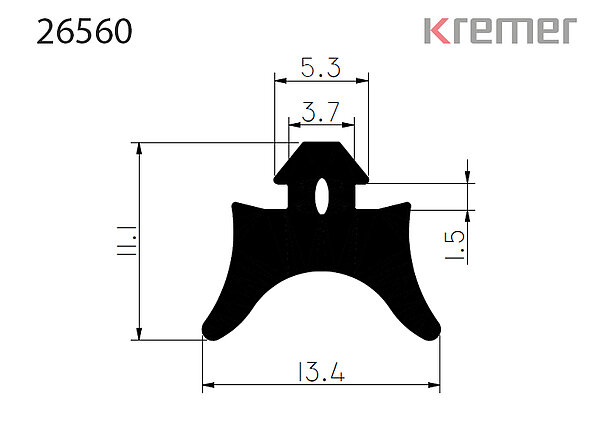

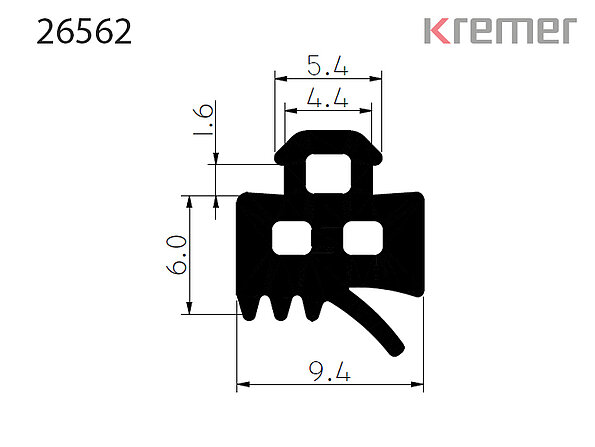

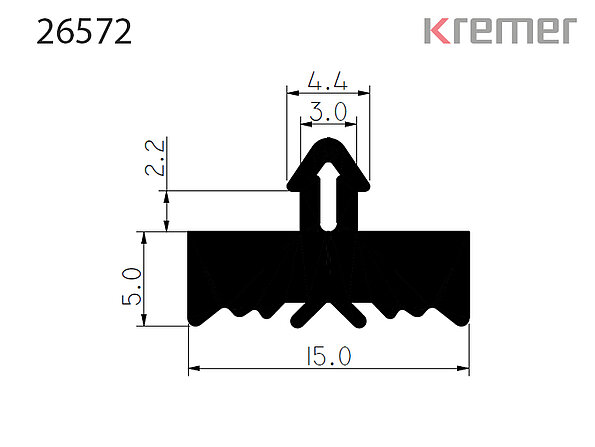

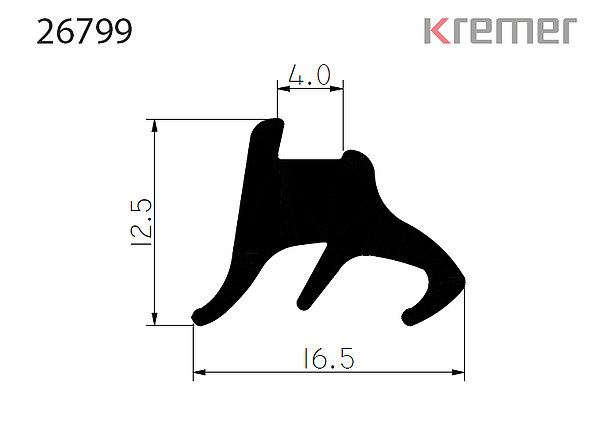

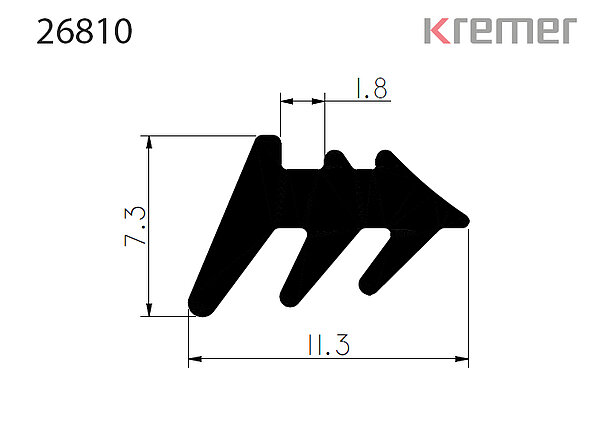

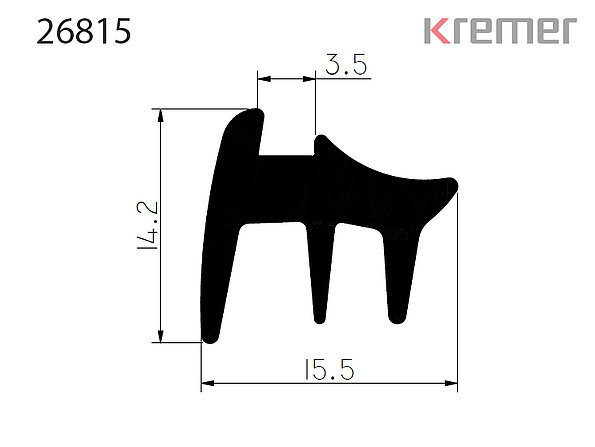

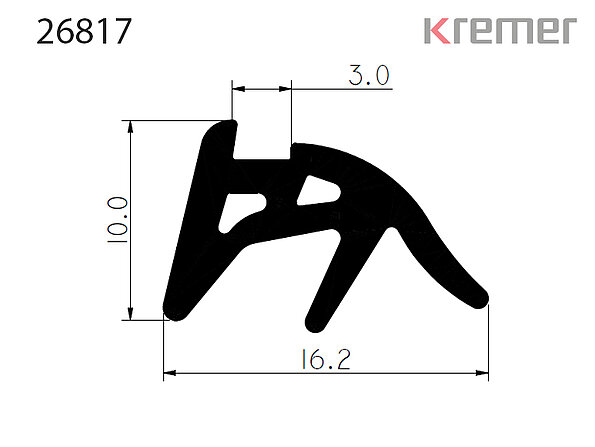

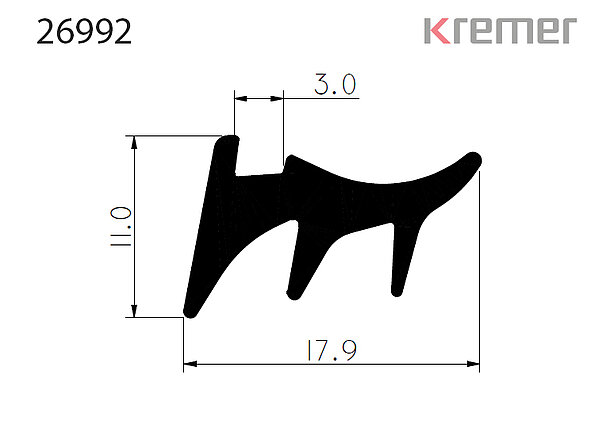

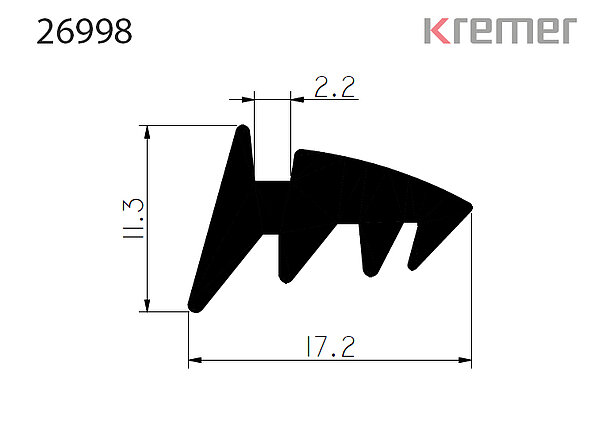

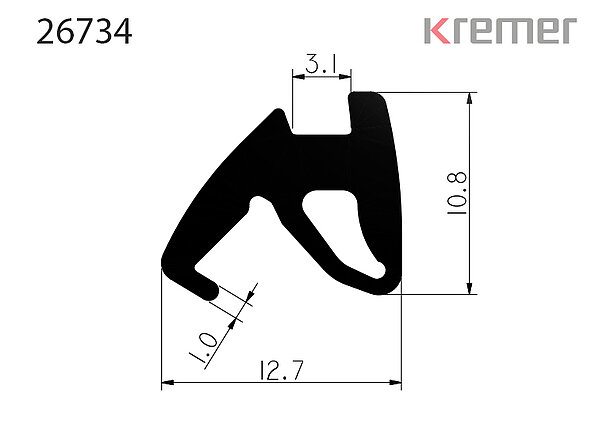

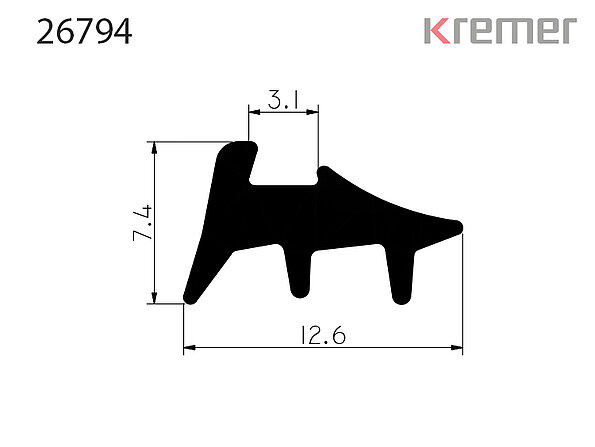

Every material and every type of profile has its own strengths. That is why customers from a wide range of sectors and industries place their trust in us. For façade, door and window construction, as well as for glass, greenhouse and container construction, we supply, for example:

- Profile aus EPDM - Krevolan®

- Moosgummiprofile aus EPDM - Krevolan®

- Profile aus Silikon - Krevosil®

- Silicone foam profiles made from Krevosil®

In general industrial applications, on the other hand, profiles such as the following are often required:

- EPDM - Profile

- EPDM - Moosgummiprofile

- Silikonprofile

- Silicone foam profiles

Of course, selecting the right material is only part of the picture. What matters is what is made from it – in terms of length, shape and type of processing. And this is precisely where KREMER is happy to assist you: with technical expertise that extends down to the smallest detail.

Rubber profiles work in detail – so let's take a closer look

A rubber profile is rarely just a piece of EPDM, foam rubber or silicone. As a sealing surface, guide, impression line, force transmission or noise damper, profiles must function precisely where they are installed: in the groove, in the rebate, under pressure, in heat or under tension.

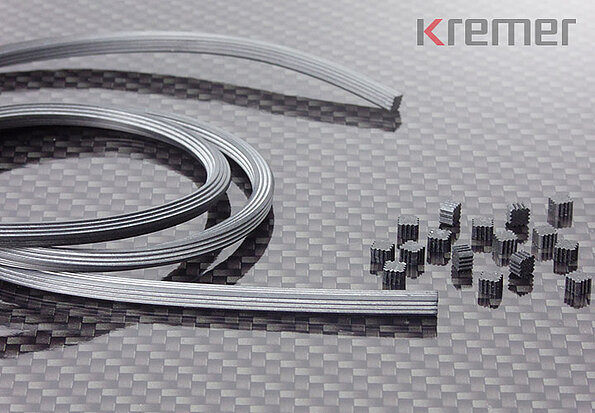

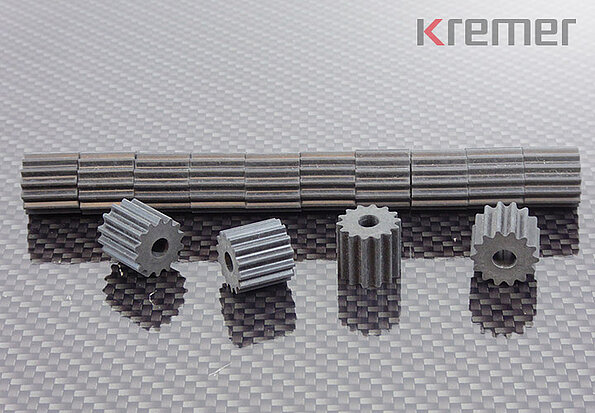

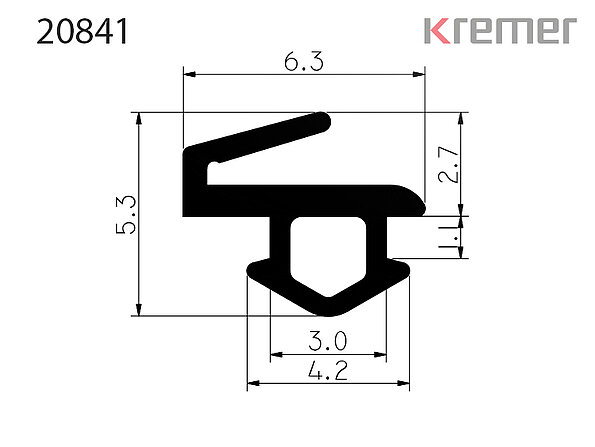

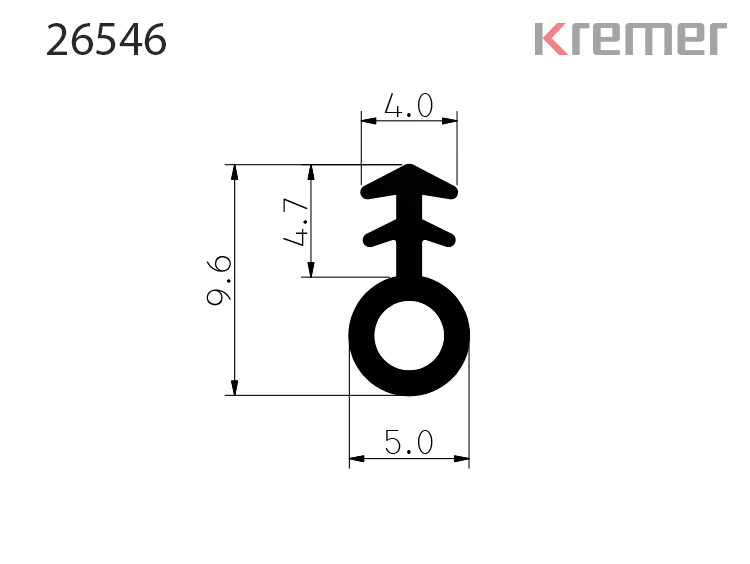

That's why we supply rubber profiles not only in different cross-sections, but also in exactly the shape you need: by the metre, as precisely cut profile sections, as vulcanised sealing rings or as corner-vulcanised frames. Depending on the geometry and hardness of the rubber profiles, we can also manufacture profile sections from a length of 4 mm. Longer lengths are of course always possible. If required, we can also equip your profiles with self-adhesive film – provided that the design and installation situation allow this.

By the way: You can check the dimensional tolerances possible for our profile sections yourself with just a few clicks using our tolerance calculation tools for rubber profiles and foam rubber profiles. The tools are based on DIN ISO 3302 and apply to extruded profile shapes, such as bulk goods or precisely cut sections.

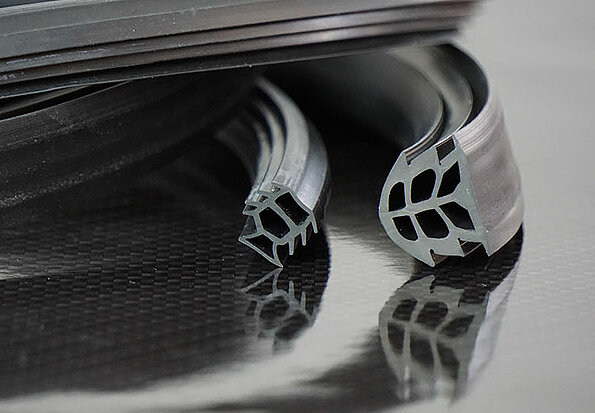

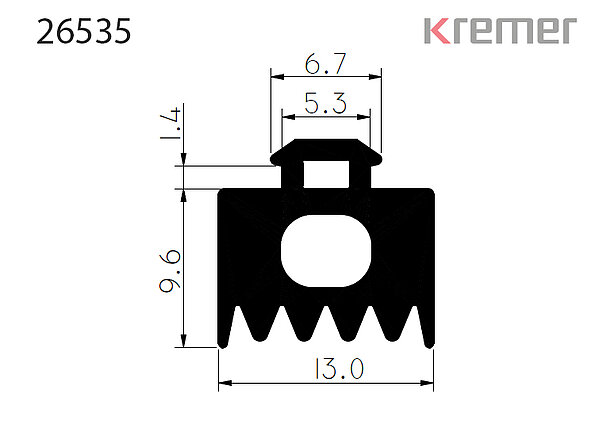

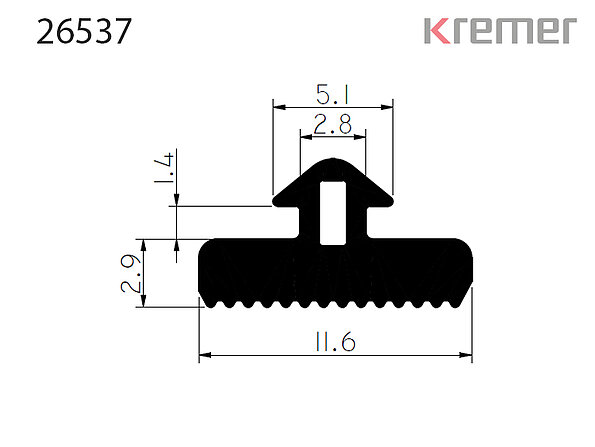

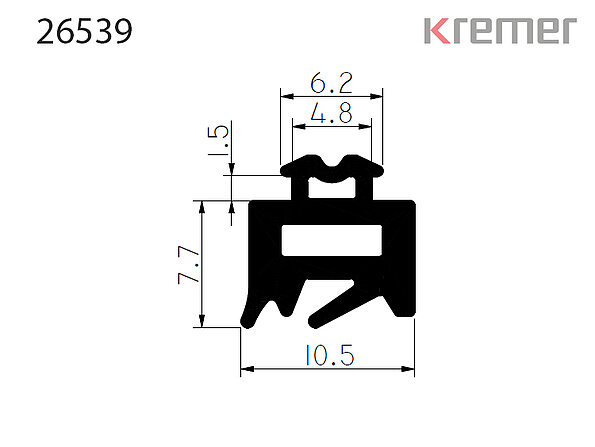

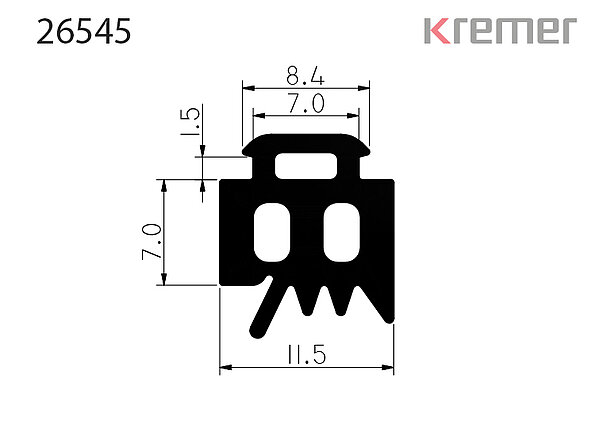

Whether as a hollow chamber profile, rectangular or T-profile, as a clamping profile for panels or edge protection profile for visible parts – when it comes to more demanding tasks, we consider both the geometry and the right interaction between materials and structure. This also includes multi-component solutions – for example, a combination of solid EPDM rubber and foamed sponge rubber when secure positioning with low closing forces is required.

How processing and material behaviour determine the function of your profiles

With materials such as silicone or foam rubber, we pay attention to every detail right from the cutting stage: surface preparation, material elongation, cutting technology – so that the finished lengths fit reliably during installation and work in practice. This is because the softer the material, the greater the effect of any inaccuracy in cutting on the subsequent fit.

This demand for precision continues at KREMER in the processing of your profiles – from bonding with cyanoacrylate to the precise film vulcanisation of silicone profiles. The result: profile rings and frames with barely visible joints – even where others have long since thought of moulding.

And if the task goes beyond this – for example, in the case of creak-sensitive vehicle components or UV-exposed PV applications – we also develop special solutions for you: from precisely fitting anti-creak profiles in accordance with VW 2.8.1 to support profiles for laminate clamps – pressure-elastic, slip-resistant and without abrasion or pressure marks.

You can count on our support even in the early project phases: with our 3D print prototyping, we can reproduce extruded profile geometries up to a length of 30 cm for you – for example, as samples for installation tests or as a basis for later series design.

Whatever the shape, material or installation requirements – in the end, what counts for us is that your profile works exactly where it should. And that it does so permanently.

Rubber profiles that fit. Processes that run smoothly. Because you made the right decision.

Profile dimensions, material, processing – everything fits your application. Your profiles arrive ready for installation, cleanly assembled and as agreed. You can plan, install and move forward – safe in the knowledge that the functional interfaces in the project are reliably covered.

So why not enquire about your rubber profiles from KREMER now? Whether you have a drawing, a sample or an idea – the earlier you involve us, the better we can respond to your requirements. You will speak to people who understand your application and can tell you how your profile can be implemented specifically and cleanly.

After your enquiry, you will hear from us within two working days – with clear feedback or an offer you can rely on. Get in touch with us now! Our team is just a message or a phone call away!

Enquire about EPDM and silicone profiles now!

Click to go directly to our EPDM and silicone profile products

Customised rubber profiles? That's why KREMER!

Three good reasons why we are the right supplier for you

KREMER thinks ahead – not only in terms of materials and geometries, but also in terms of processes, requirements and functions. You will always be dealing with people who understand exactly what you need. This results in rubber profiles that fit perfectly and perform exactly as they should in operation.

When it comes to rubber profiles, every hour counts. That's why we keep things short: you speak directly to our expert advisors – no waiting on hold, no ticket system. Once we receive your specifications, you will usually receive a precise response or a concrete offer within 48 hours. For maximum predictability in your processes.

Every profile is manufactured to fit perfectly – in terms of geometry, material and workmanship. Whether you need metre goods, cut-to-length pieces, rings or frames, you will receive a product that is exactly right for your application and performs its function reliably.

Numbers – Data – Facts

Profiles division

Number of profiles delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Request expert advice now!

Haven't found what you're looking for on our product pages? Then we are happy to help!

You can use the following enquiry to contact our experts directly and describe your product in more detail. Our specialist advisors look forward to receiving your enquiry and will get back to you as soon as possible!

Contact

Request a consultation now!

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

KREMER calculation tools

Further information

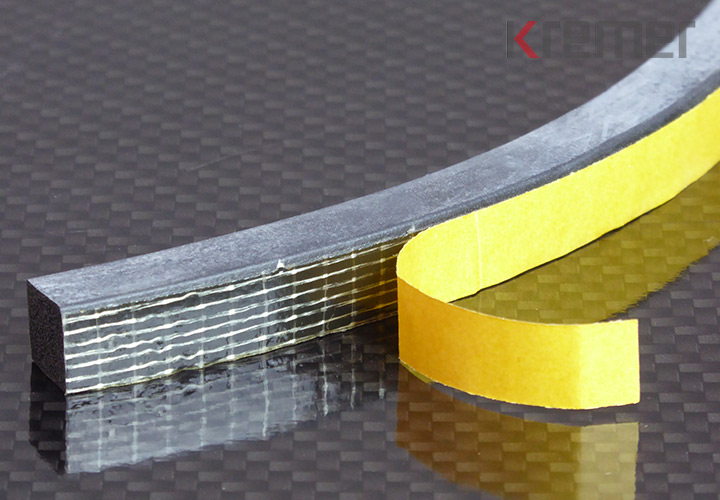

Simple installation with self-adhesive film

Especially when long sections need to be fitted with profiles, the use of self-adhesive film as an assembly aid is a practical support and simplifies the fixing of the profile during assembly.

Storage time limited

Profile seals equipped with self-adhesive film can only be stored for a limited period of time. Due to the chemical composition of the film, the self-adhesive profile may also have a shorter shelf life. This shelf life is shorter than the warranty period of twelve months for self-adhesive profile seals. Please be sure to observe the storage and processing instructions.

Professional tip: For optimum processing, the profile seals should be stored in an unopened box and processed within six months.

Temperature and processing

- Optimum bonding temperature between 20°C and 30°C in dry rooms.

- Do not process below 10°C.

- Storage temperature at 20°C and approx. 50% relative humidity.

- Ensure that surfaces are clean, dry and, if possible, smooth - this produces the best results.

- Only remove the protective film immediately before use. This prevents adhesion-reducing contamination with dust and moisture.

- It is essential that you ensure even and full-surface contact. The contact pressure must be sufficient and even. Both the hands and the application tools must be free of release agents (especially oils and greases).

- The profile to be fixed should not hang for longer than 30 minutes without support.

- Please note that the maximum adhesive strength is only reached after approx 24 hours in the case of extreme loads on adhesive joints.

- The profiles should be processed in such a way that a permanent stress effect on the bonding is avoided.

Prerequisite for the warranty for self-adhesive products

Self-adhesive profile seals must be processed within six months of delivery, taking into account the above-mentioned storage conditions (temperature, humidity and other processing instructions). We cannot accept any liability / warranty for products processed at a later date.