Moulded parts and injection-moulded parts made of PVC

Durable moulded parts and injection-moulded parts for series production

Durable moulded parts and injection-moulded parts for series production

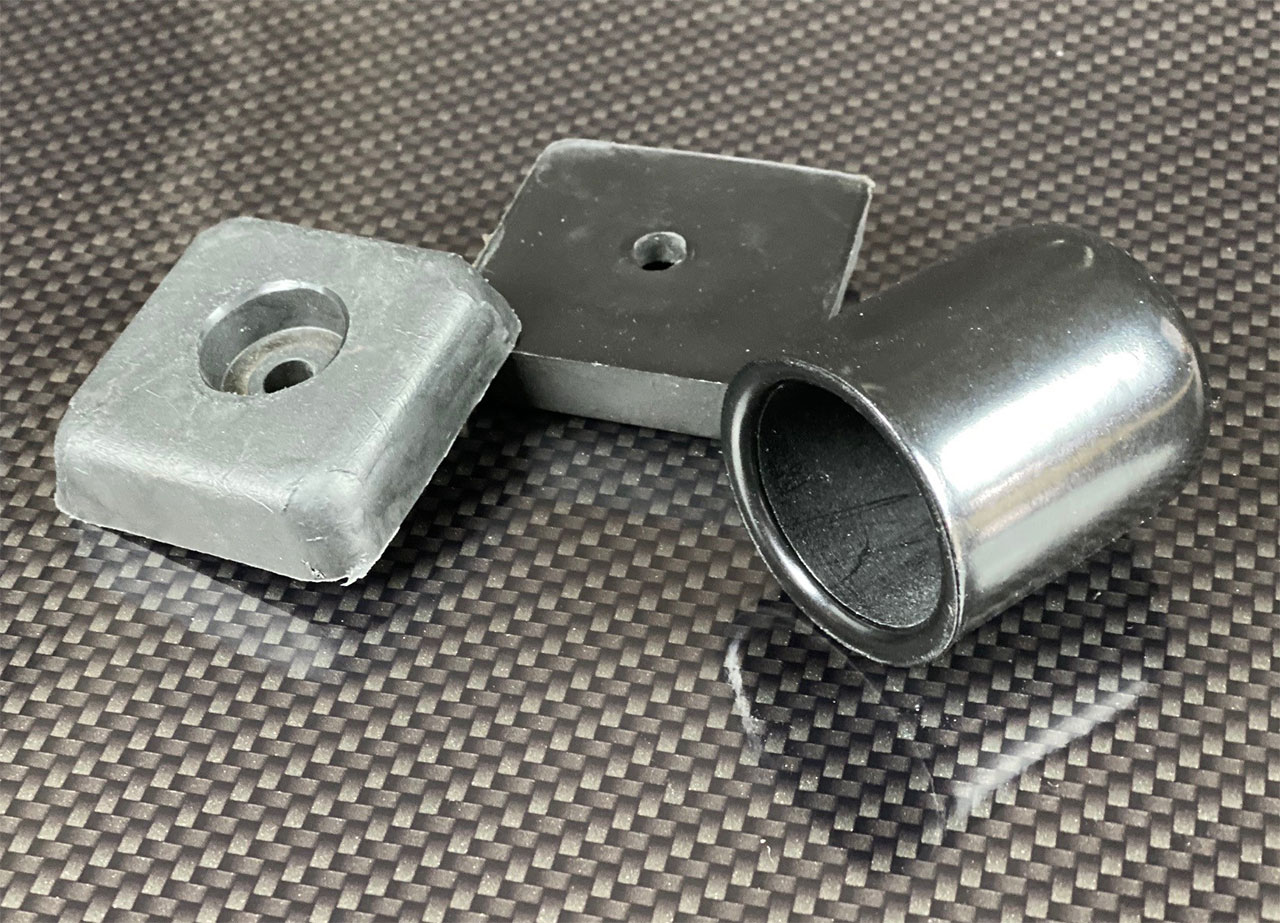

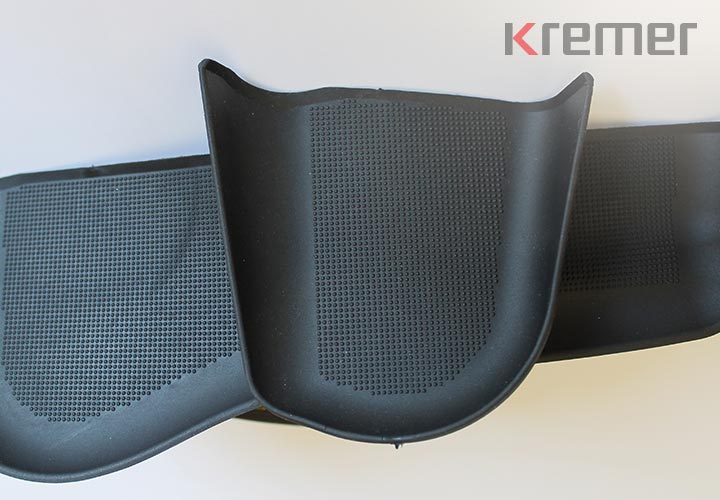

PVC, or polyvinyl chloride, is one of the best-known standard plastics with outstanding properties, but it is not without controversy among the general public. The addition of plasticisers makes it flexible, malleable and suitable for an enormous number of technical applications. Most people know PVC for its excellent electrical insulating properties as a material for cable sheathing, its softness and flexibility for the manufacture of cable grommets, anti-kink sleeves, bellows and, due to the transparency of the elastic PVC material, for processing into cover caps for rocker switches, e.g. ON-OFF switches for machines that are exposed to the weather.

Soft PVC is a hard-wearing, versatile thermoplastic with good resistance to alcohol, petrol, alkalis, oil and acids, and can also be easily dyed or made crystal clear. The moulded parts and injection-moulded parts made of PVC have a glossy surface if the surface finish of the injection moulding tool is appropriate.

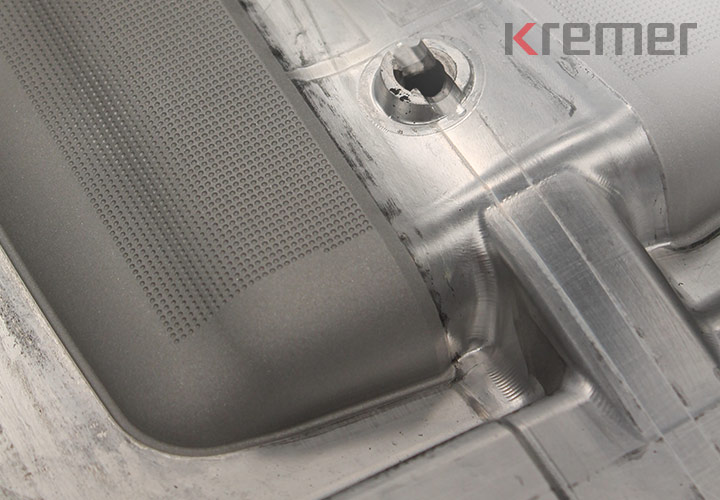

When injection moulding soft PVC parts, the material is heated to a melting temperature of 160-200°C and injected into a specially designed injection mould at high pressure. In the cooled mould, the soft PVC compacts, cools and becomes dimensionally stable during the cooling process. The moulded part can then be removed from the mould semi-automatically (manually) or ejected fully automatically or removed using a handling device and deposited in a deformation-proof manner. With fully automatic production, very large quantities can be produced economically.

If a tool-bound moulded part is expected to have a short service life or lifetime, the construction of an aluminium tool can sometimes help to save money and costs. You can find more information here.

Properties of soft PVC at a glance

Existing

-

Shore Range

50 to 90 -

Temperature Range

-10°C to +60°C -

Petrol

Feature available -

Weather

Feature available -

Cleanser

Feature available -

Gas

Feature available -

Sea Water

Feature available

Optional

-

Oil Grease

on request -

Ozone

on request -

Food

on request (FDA compliant)

The cost-effective alternative to injection moulded parts - dipped parts made of PVC

It should be noted at this point that handles and caps made of PVC can very probably be offered more cost-effectively than PVC dipped parts, depending on the intended use and geometry. With our own Krevosol® brand, we produce round caps, rectangular caps, paint covers and general caps for transport protection in a variety of dimensions, standard and special colours in a very short time and almost always without tooling costs, except for customised geometries.

More on the topic PVC immersion parts.

PVC castings - for large wall thicknesses

Thick-walled PVC cast parts with and without metal inserts are not only required in the wind power industry. Due to the unpressurised manufacturing process of casting, cast parts can be produced at low cost for tools. We work with you to determine whether the product you require can be manufactured and offered as a dipped part or a moulded part during a preliminary quotation discussion, which forms the basis for our offer.

Material tip! Flame retardant

In contrast to other engineering plastics such as polyethylene (PE) or polypropylene (PP), soft PVC is difficult to ignite due to its high chlorine content and quickly extinguishes once an open flame has been removed. However, fires involving PVC plastics produce hydrogen chloride, dioxins and aromatics.

The three pluses of KREMER

KREMER - always a good decision.

Personally there for you!

The variety of applications for soft PVC molded parts is so great that it requires an expert. This is exactly what you will find at KREMER. From inquiry to delivery, you will be advised and served by a specialist. We can support you perfectly with prototyping, especially for PVC molded parts. This allows you to get your prototypes quickly and economically for dimensionally accurate development work.

Know how!

There are 1,001 approaches for many tasks. Working out exactly the right shape, the right material and the right assembly is our daily business. We use our knowledge and creativity for your product and assure you that we always keep an eye on the economic requirements.

Perfection!

That is what we strive for - with every new order. Perfection in order processing, the manufacturing process and product quality. TQS - that means Total Quality System, and we are committed to it. Put your trust in KREMER.

Numbers – Data – Facts

Information from KREMER

Number of molded parts delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Enquiry PVC moulded parts

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.

Further information

Injection molding tools made of aluminum

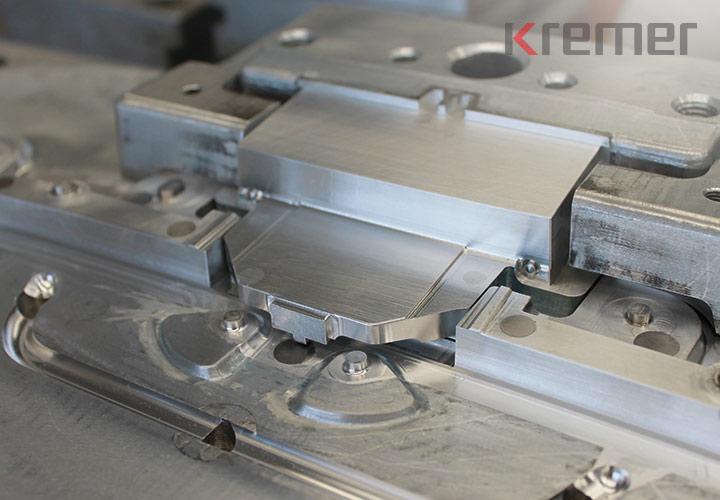

The production of tools for injection-molded Molded plastic parts or TPE Depending on the geometry of the molded part and the processing steps required in toolmaking, small and medium quantities are a not insignificant cost factor. A decision must be made on a case-by-case basis as to which type of mold should be used. One criterion for the pros and cons is the investment decision.

We offer the advantages of aluminum tools suitable for series production to innovative industries that only target a limited group of customers and therefore do not think in terms of large quantities. Aluminum tools are not only suitable for the production of Prototypes suitable. They offer considerable price advantages for the series production of small and medium quantities. For example, aluminium tools are around half the price of steel tools.

Advantages of aluminium tools

- Significantly lower tool costs compared to steel moulds

- High milling speeds

- Lower hourly machine rates in toolmaking

- No finished part distortion, as the aluminium injection moulds can be equipped with cooling channels as with steel moulds

- Realisation of identical surfaces as with tool steels is possible (eroding, etching, polishing, etc.)

- Significantly higher thermal conductivity compared to steel

Especially for the production of small quantities, the higher thermal conductivity of aluminium has a considerable influence on the heating and cooling speed of the tool and thus on the production time and production costs of the product series.

Alternatively, there is always the option of testing 3D printing. The KREMER team of experts uses its in-depth knowledge and experience to provide advice and is familiar with the advantages and disadvantages of the respective mould processes and Prototyping-Applications.