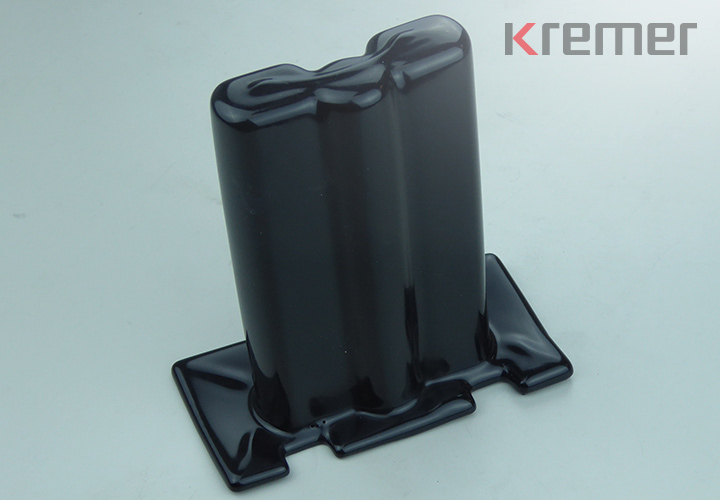

Immersion parts made of PVC

KREMER manufactures PVC-Krevosol® standard round caps and rectangular caps

PVC-Krevosol® standard round caps and rectangular caps for commercial customers

Are you a commercial customer in need of PVC dipped parts that are precisely tailored to your application and that not only have to be delivered quickly by your supplier, but also have to meet the highest quality requirements?

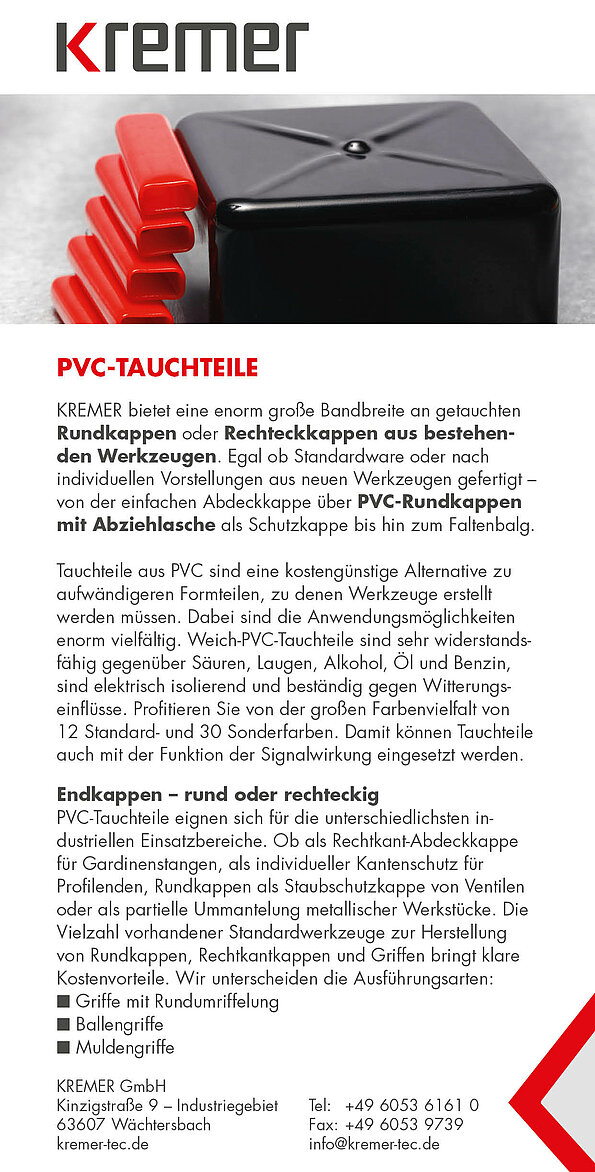

KREMER offers an enormously wide range of dipped round caps or rectangular caps made from existing tools for industrial purposes. Whether standard products or manufactured from new tools according to individual requirements - from simple cover caps to PVC round caps with pull-off tabs as protective caps and bellows.

PVC-Krevosol® sheathing and coatings

In addition to various parts made of soft PVC Krevosol®, KREMER also offers you the sheathing and the PVC dip coating of metal parts – as you know it from the ends of pliers handles or latches, for example.

To do this, we immerse the metal blanks in plastisol for a defined time and depth after heating. The PVC adheres and forms an electrically insulating layer. A special type of our Krevosol® PVC grades with additives is available for ESD requirements. Perfect work protection for pliers.

PVC dipped parts - individually manufactured according to your specifications and wishes

The starting point for the production of all immersion parts is a natural transparent PVC base material. This transparent PVC base material can be used to produce dipped parts of various hardnesses, but also a Krevosol® PVC type that allows a view through and thus, for example, a view of digital or analog displays located behind it. The dipped part itself could be used as splash protection, for example.

Vortex sintering for wear and corrosion protection

At KREMER, we don't just rely on standard processes, but offer innovative, adaptable solutions for specific requirements. We use the fluidized bed sintering process to achieve a particularly uniform coating and a precise layer thickness. The modern coating process with PVC and polyamide is ideal for coating metal parts that need to be protected against wear and corrosion.

- Custom colors and finishes : In addition to the standard color black, we can offer almost any color upon request to meet the aesthetic and functional requirements of our customers.

- Combination with dip coating : After sintering, the parts can be additionally refined with a partial dip coating . This enables targeted reinforcement of the coating in areas subject to particular stress.

- Extended material selection : We not only offer coating with polyamide and PVC, but can also use alternative materials for special applications on request.

- Increased abrasion resistance : Our polyamide coatings have a hardness of 90 degrees Shore A , which offers exceptionally high abrasion and chemical resistance – ideal for extreme operating conditions.

- Sustainable production : KREMER relies on environmentally friendly processes in which excess powder is recycled to minimize waste and use resources efficiently.

By adding colour batches, KREMER offers you a wide range of colours, which is particularly important when the signal effect of the dipped parts needs to be optimized in addition to the desired dipped part function. As a commercial customer, you can choose between 8 RAL standard colors or 30 other special colors. A large number of tools are already available for the production of standard dimensions, which is why we can manufacture and supply you with PVC caps quickly and cost-effectively.

Choose the color of your immersion parts from one of our eight RAL standard colors:

Photoluminescent PVC caps and coatings

A special color pigment is responsible for absorbing the energy of the light and gradually releasing it again, e.g. in a production plant in the event of a sudden darkness caused by a power failure. This creates the effect of afterglow.

The milky white color of PVC round caps and rectangular caps or PVC-coated metal parts such as door handles and levers turns green in daylight. Although the intensity of the afterglow decreases as darkness continues, the effect of the afterglow can still be seen very clearly for a while in the event of a sudden emergency.

For companies that operate chemical processes with acids and alkalis, it is absolutely essential that a blind eye can still see this color in the event of an emergency.

The color pigment used can be mixed into all PVC Krevosol types without negatively affecting the specification of the material. This applies to the phthalate-free Krevosol types for medical or orthopaedic applications as well as to the biocompatible Krevosol 1649. The only exception is coloring for ESD applications, as the electrical surface resistance can only be achieved with the color black.

Tolerances and hardening for PVC dipped parts

The following tolerances apply to the usable inner length of caps and the wall thickness of caps for the manufacture of dipped parts:

- Height (inner position): +/- 2,0 mm

- Wall thickness: +/- 0,25 mm

The standard hardness of our PVC dipped parts made of Krevosol ® is 68 Shore A. On request, we can also offer you two harder settings in 85 and 96 Shore A and a softer setting in 55 Shore A for the manufacture of bellows.

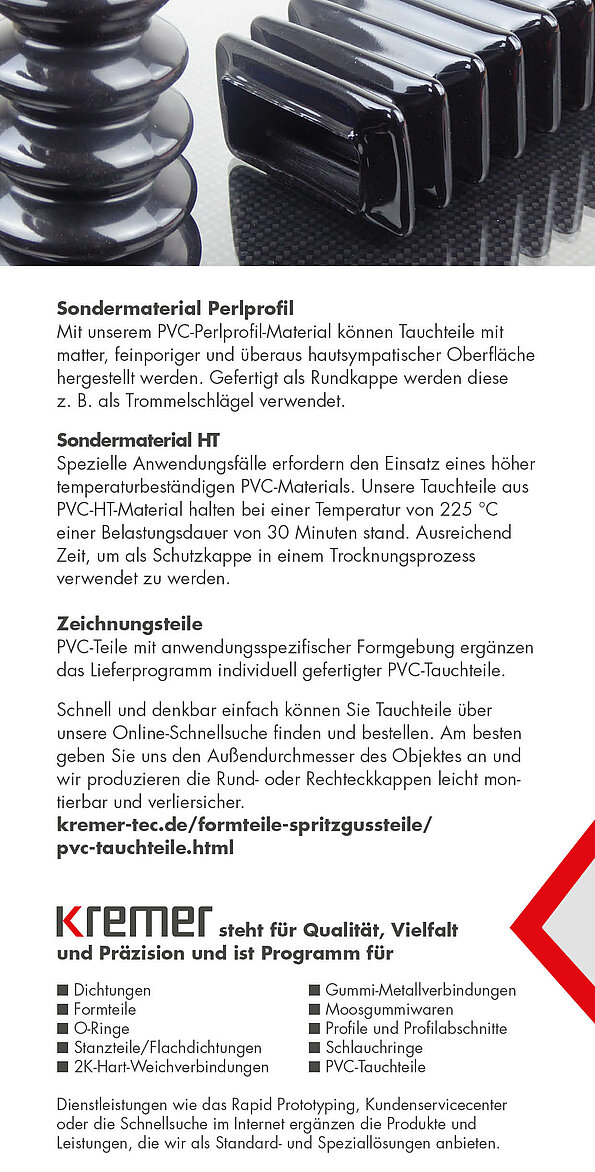

PVC special material with pearl structure look

We achieve dipped parts with a matt, fine-pored and extremely skin-friendly surface by using our PVC-Krevosol ® types with a pearl structure look. These are available in six colors,

- black,

- sky blue,

- red,

- green,

- orange and

- light gray

can be supplied. KREMER is happy to offer you the special settings mentioned on request. PVC dipped parts with a pearl structure look have a surface with a better grip. This surface structure is used for drumstick handles and prevents them from slipping out of wet hands. They also give customers the impression of a higher quality appearance.

PVC special material HT (higher temperature resistant)

Special applications require the use of a higher temperature-resistant PVC material. Our immersion parts made of HT material can withstand a load of 30 minutes at a temperature of +225°C. An empirically determined formula describes the service life as a function of the service temperature: with a 10 Kelvin higher service temperature, the service life is reduced by 50% and vice versa.

- Example 1: Application temperature 235°C = 225°C + 10K = (30min -50%) = 15 min.

- Example 2: Operating temperature 205°C = 225°C - 2 x 10K corresponds to ((30 min. + 50%) + 50%) = 67.5 min.

The high-temperature special material HT is ideally suited for the use of flexible caps as protective caps or cover caps. It can also be used as paint protection during powder coating of metallic products, which takes place at higher temperatures of approx. 180°C. Round caps and rectangular caps as well as freely defined geometries protect the surface areas that are not to be powder-coated.

As a rule, caps can be used as paint covers several times at 180°C for around 15 minutes during powder coating before they become brittle and hard over time and need to be replaced with new caps. When removing the caps after powder coating, it is important to ensure that the PVC protective caps have cooled down to avoid deformation.

How can we help you? Our wealth of ideas and user experience in the field of immersion parts is enormous. Benefit from this as a commercial customer and let us advise you at the start of your project. As soon as all specifications have been clarified, we will send you a individual offer!

Detailed material information on the standard and special PVC-Krevosol® grades and colors can be found on the corresponding product pages and in our Download area.

PVC dip caps and their application

We manufacture and supply over 30,000 variants of round and rectangular caps from a wide range of standard tools for our commercial customers and their various applications. Are you looking for round protective caps that are easy to fit but still secure? KREMER can supply you with round caps that meet your requirements! Whether for protecting screws, drills, measuring gauges, as transport protection or as protection against injury - the principle is always the same.

The easy-to-fit PVC rectangular or round caps protect the metal part of your components from damage or prevent injuries. PVC as a material is very flexible and pliable. This means that even round objects can be protected from damage with a rectangular cap that is actually straight. Please ask us about your individual requirements.

Other PVC dipped part products

One click takes you directly to our PVC dipped part products.

PVC dipped parts? Therefore to KREMER!

Three reasons that will convince you to choose us as your supplier for PVC dipped parts:

Experience and expertise

Tried and tested dipped parts made of Krevosol ® soft PVC are used in a number of areas of industry, which is why they are manufactured in countless variants and meet a wide range of requirements. Regardless of whether you know exactly what your soft PVC dipped parts need to be made of or whether you need more detailed advice: In both cases, it is important that your supplier has in-depth experience and expertise.

This is exactly what you will appreciate about KREMER employees. In the course of our 60-year company history, we have already supplied a large number of customers with a wide variety of PVC dipped parts, which have always had to meet different criteria. Based on this experience, we can not only offer you the most economically interesting option for you, but also help you with our know-how if required.

Saving time during procurement

Protective caps, Rectangular caps, Round caps & Co. are classic C-parts that are often only thought of at the end. And then everything has to happen very quickly. Specification, quotation, delivery. We are prepared for this challenge and therefore work particularly efficiently for you:

As soon as we receive your inquiry with all the details and specifications for your desired diving parts, we will provide you with a transparent, informative quote within 24 hours and, in the case of individual inquiries, a quote tailored to your requirements within 48 hours. You can also find out in advance thanks to our quick search for Round caps or rectangular caps after entering the required dimensions, whether a tool is available for production and which standardized lengths are available. If a tool is available, delivery can usually be made very quickly.

High quality, precisely tailored to your requirements

Although PVC dipped parts can be produced quickly and cheaply in large quantities, they must also be 100% adapted to your application in order to function reliably. To ensure this and to meet your high quality requirements, we at KREMER rely exclusively on suppliers and partner companies with whom we - and therefore our customers - have already had positive experiences over the long term. In addition, we are also ISO 9001:2015 certified and pay attention to ecological and ethical criteria when selecting our suppliers.

Numbers – Data – Facts

Information from KREMER

Number of molded parts delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Request PVC dipped parts now!

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Application examples of Krevosol ® PVC dipped parts

Adhesive tapes of various types are often used as paint protection. After the painting process, the adhesive tapes are removed from the part to be protected and thrown away. This is not environmentally friendly in terms of conserving resources. The paint cover from KREMER in the form of a dipped part fulfills a triple benefit.

On the one hand, it serves as secure paint protection for the object and, on the other, as protection against damage to the area not to be painted. The dipped part can be used several times and is often easier to handle than adhesive tape. Dried layers of paint can be removed by bending the flexible paint cover.

The metal part, which is usually to be protected from the paint application at certain points later on, serves as the starting point for the production of the protective cap, the so-called paint cover.

The original metal part is therefore the dipping tool, which is first dipped into the PVC paste as required and removed after a specified dwell time. The resulting PVC cover is demolded and, if necessary, manually finished for use as a cover.

The resulting paint cover is a 1:1 negative copy of the area to be protected on the original metal part and therefore fits straight away.

Metal hooks used to hang and store objects, equipment and tools can pose a risk of injury to employees. Injuries can be caused by careless handling, cutting on sharp edges or impact on the hook protruding from the wall. Sometimes such hooks are simply overlooked.

The risk of injury could be avoided by using a visually striking and loss-proof protective cover. KREMER proposes a solution that depends on the geometry of the metal hooks and the type of mechanical stress.

PVC dip coating/sheathing of round parts

If, for example, the metal hooks are made of round steel and are subject to regular mechanical stress, we recommend wrapping the ends of the hooks.

Procedure: The metal parts to be coated are pre-treated with a primer (adhesion promoter) and then coated with PVC using an immersion process. The wall thickness of the permanent PVC coating is usually approx. 1.8 to 2 mm. PVC with a hardness of 75 Shore A is always available in 16 standard colors - including the signal colors red and yellow - for the production of dipped parts.

Use of PVC round caps

An alternative to the coating of metal parts is the overcoating of dipped parts. PVC round caps. Prerequisite: The cap must be tight and secure. To ensure easy installation, the caps are manufactured with the necessary small undersize compared to the diameter of the round hook. The 68 Shore A soft PVC material allows the caps to stretch slightly so that they can still be easily slid over the ends to be protected. The greater the inner length of the round caps, the lower the risk of the round caps being stripped off when the hooks are used.

Perfect protection for sharp tools

The PVC caps are used to protect the razor-sharp cutting edges of precision drilling tools from damage. They fulfill important basic requirements. One essential requirement is that they are easy to fit. It must be ensured that they are not fitted too loosely, but are sufficiently tight so that they do not get lost during transportation.

The chemical composition of the soft PVC material ensures that no oxidation (no rusting) is triggered on the metallic products. Thanks to the eight standard colors and 30 special colors available to us, KREMER was able to produce the caps in the company color. An additional, sales-promoting benefit for the customer.

What we look for when choosing the dimensions/design of the immersion parts

Whether caps (Round caps, Straight edge caps) on an object (cutting edges of drills, milling cutters, precision joints of electrical connectors, openings of valve seats, etc.) or simply as a handle on a piece of pipe, it is important that the immersion parts are manufactured undersized to ensure a tight fit. We can suggest the right size for you in our quick dip part search.

As a rule, the diameter of dipped soft PVC round caps should be approx. 0.5 to 1 mm smaller so that a secure fit is achieved and the cap does not come off too easily or even detach from the product to be protected, e.g. due to vibrations during transport.

If you are interested in these products, please select the Direct enquiry.

Split split ring with pearl structure

Product requirement: A new type of fabric sling on the hunting rifle takes the strain off the hunter when holding and repeating the rifle. The hunting rifle lies more comfortably in the hand and is held securely in position by the muscles in the biceps. A metal hinged split ring is used to adjust the "sling" precisely to your own body measurements and the hunting rifle.

Special feature: The standardised hinged pin ring must not have a metallic sheen to avoid reflections and must not rattle when attached and when firing.

Solution: Instead of a black powder coating, the hinged split ring was given a PVC coating by dipping, which resulted in a matt and fine-pored surface, the so-called pearl structure look.

The advantages of pearl structure optics:

- The dark and matt structure prevents reflection,

- avoids rattling noises and is also

- Absolutely UV and weather resistant.

Occupational safety for roofers

The sole marketer of the patented single-sheet system quickly found help. The handles of the roofing tools had sharp edges, which often led to cuts when force was applied.

The handles, which serve as levers, are now covered with the pearl profile. This soft PVC material sits securely in the hand, allowing greater force to be applied and is also UV and weather-resistant. The roofing handle is therefore not only easier to handle but also of a higher quality overall and increases occupational safety.

Download info card "PVC dipped parts"

to the download area "Info cards"

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.