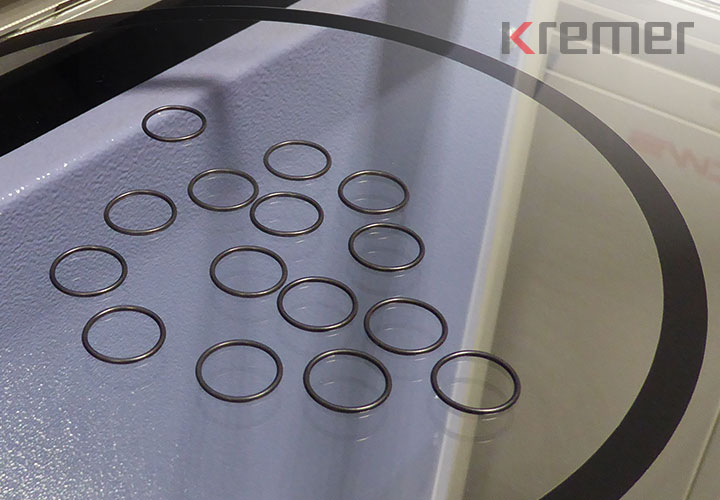

FKM O-rings: Thermally and chemically resistant

FPM / FKM: The thermally and chemically resistant O-ring material

KREMER manufactures FKM O-rings - also as FPM or under the trade nameViton® in a variety of standard dimensions and special designs. The fluoroelastomer material FPM / FKM has excellent chemical resistance and fulfils the following requirements, among others:

- High temperatures

- Oxygen, ozone and weather influences

- Chemicals, fuels, mineral oils, aromatics, many organic solvents, synthetic hydraulic fluids

- low gas permeability

- Wide operating temperature range between -40°C and +200°C

These properties make FPM / FKM O-rings ideal for use in high-vacuum applications, mechanical devices and the automotive industry. Do you need FKM O-rings that have a lower compression set, higher resistance to acids, fuels, water and water vapour or an even wider temperature range? Or does your product require O-rings made from special FKM compounds with Freigaben nach DVGW or FDA? The KREMER sealing experts know the ins and outs and can provide you with comprehensive advice.

Due to the already quite low tendency of FPM / FPM O-rings to adhere to the surfaces of friction partners, the need for a zusätzlichen Beschichtung is considered to be rather low.

You can check your specific material requirements, which you made with the material preselection FPM / FKM, with a tool that clearly displays the chemical resistance to a specific chemical in comparison to the vast majority of elastomer materials

We offer your responsible employees in the specialist departments assistance in the development and design phase with two other very useful calculation tools. On the one hand our Einbauberechnung O-Ringe and on the other hand our Toleranzberechnung O-Ringe.

Weitere nützliche Informationen and answers zu häufig gestellten Fragen (kurz: FAQ) round off our claim as a service partner and supplier to the industry.

Existing

-

Shore Range

50 to 90 -

Temperature Range

-25°C to +200°C -

Oil Grease

Feature available -

Petrol

Feature available -

Diesel

Feature available -

Ozone

Feature available -

Weather

Feature available -

Cleanser

Feature available -

Steam

Feature available

Optional

-

Extreme Temperature

down to -40°C on request -

Gas

on request -

Food

on request (FDA compliant)

FKM / Viton® O-rings? KREMER - the expert

Our customers confirm this:

Always the right O-ring material for your application

As varied as the applications in which our customers use FKM O-rings are, so too are the FKM compounds and the details that are important when using them. It is important for you that your O-ring supplier knows the intricacies and can offer you FKM O-rings that exactly match your specifications.

At KREMER, we are geared towards these customer requirements. When you speak to our employees, you can be sure that they understand your task in detail and that we can supply you with the FKM O-rings that are ideally suited to your application based on your specifications.

Time savings in O-ring procurement

The time factor plays an important role for most of our customers. Their production and delivery processes must continue seamlessly, which is why fast, transparent and informative quotations are required.

This is another of KREMER's strengths. You can rely on our O-ring consultants to provide you with a customised quote for your FKM O-rings as soon as we receive your enquiry with all your specifications. We respond within 24 hours on working days. This speed is also reflected in our delivery times, so that once we have all the detailed information on FKM / FPM O-rings, we can usually also provide a delivery time.

Highest quality standards for FKM O-rings

You not only attach importance to the high level of expertise of your O-ring supplier, but also to the quality of the products - the decisive factor for process reliability and product quality in your company. There are therefore clear requirements that your O-ring supplier must fulfil.

At KREMER, we make no compromises. From the very beginning - that is, for over 60 years - quality has been our top priority in all areas. Our customers know this and rely on KREMER.

We are also ISO 9001:2015 certified and select our suppliers according to qualitative as well as ecological and ethical criteria. This enables us to guarantee you exactly the high quality you expect at all times.

DVGW type examination certificate

We have received a type examination certificate for our FKM material from the German Technical and Scientific Association for Gas and Water (DVGW). FKM from KREMER fulfils the DIN 549 standard, which specifies the requirements for elastomer materials for seals and diaphragms in gas appliances and gas systems.

The Zertifikat "DVGW-Baumusterprüfzertifikat" confirms that our material corresponds to temperature class E2 with a particularly wide temperature range of - 20 to + 150 °C. The material therefore has the widest possible operating temperature range.

The 70 Shore A material also has a hardness range of H3 (from > 60 to 90 Shore A) and is available in the colour green. This makes it visually different from the standard FKM colour black. Perfect for seals in gas appliances and systems.

Numbers – Data – Facts

O-rings business unit

Number of O-rings delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.

Hardness measurement - sophisticated quality management for O-rings

The hardness of O-rings is measured according to Shore A, Micro-Shore or IRHD (International Rubber Hardness Degree). KREMER has decided in favour of laser-based Micro-Shore hardness measurement, as our customers want to see the hardness of the finished O-ring and not the Shore A hardness of the 6 mm thick material test plate documented.

The requirements for the surface structure of O-rings are becoming increasingly demanding. In addition to the miniaturisation of components, the surface structures of O-rings are also subject to increasing functionalisation.

According to DIN 3771, O-rings must be measured without contact and therefore non-destructively. This applies to the dimensions of the O-rings as well as to surface defects.

KREMER uses non-contact, opto-electronic measuring and sorting devices that provide very precise data and analyse a large number of quality-relevant parameters. Quality control can also be perfectly documented by optical measurement.

The optical-electronic measuring devices guarantee extremely precise measurements and the realisation of a sorting of previously clearly defined characteristics. This is the only way to separate good parts from bad parts with a zero error rate and fulfil the requirements for PPM rates, e.g. in the automotive supply industry.