Silicone seals

Made to measure according to customer requirements

Made to measure according to customer requirements

We supply silicone seals in a wide range of variants that will convince you. For example, if you are looking for silicone seals with the following material properties:

- Excellent ozone and weather resistance

- Resistance to high temperatures and wide temperature range (-55°C to +210°C)

- Excellent insulating properties

- Food-safe

- Good media resistance to oils, fuels or chemicals

- then KREMER is the right place for you!

These properties ensure that silicone seals are ideal for a wide range of applications - from the chemical industry to aerospace and defence. Automobil-Industrie, KREMER has specialised in the manufacture and distribution of tool-bound seals and moulded parts for the food industry with corresponding approvals (FDA, BfR), in particular also from the material silicone.

Our product portfolio includes, among other things

- Flat gaskets,

- punched and water jet-cut gaskets,

- Profile seals and

- Silicone foam seals.

Overview of silicone properties

Existing

-

Shore Range

20 to 80 -

Temperature Range

-55°C to +200°C -

Ozone

Feature available -

Weather

Feature available -

Food

Feature available -

Sea Water

Feature available

Optional

-

Extreme Temperature

-90°C to +250°C on request -

Steam

on request

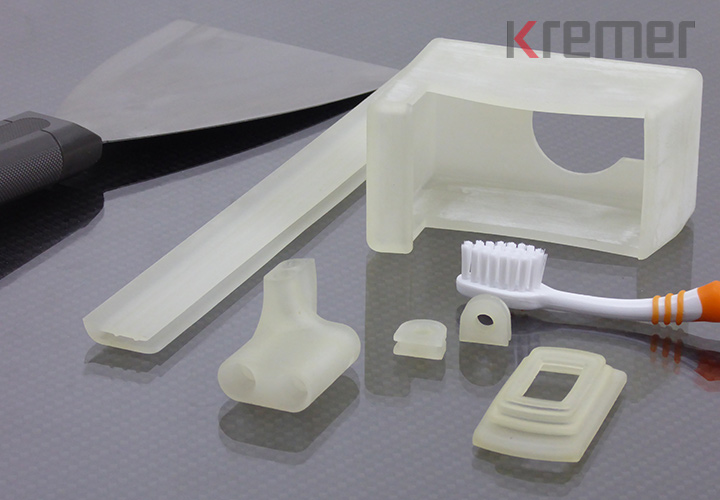

3D printed seals

As a special service, we would like to present the production of 3D-printed prototypes made of silicone-like elastomer material in hardness grades 35 and 65 Shore A. With the help of the printed prototypes, geometry changes and their influence on the function or assembly situation can be achieved in the run-up to investment decisions for the construction of silicone injection moulds. The silicone seals are always customised precisely to your specifications.

Get in touch with us and let's talk about your sealing application!

Customised silicone seals? KREMER is the right place for you!

Three good reasons in favour of KREMER:

High expertise of our employees

It is important to you that your silicone sealant supplier knows the exact requirements and specifications that you need and is able to provide you with expert support. After all, you need silicone gaskets that are precisely tailored to your sealing application. Expertise is one of the strengths of KREMER employees.

For over 60 years, we have been supporting customers from a wide range of sectors and industries with customised silicone seals. In the process, we have become familiar with all the intricacies and details that are important here. You can be sure - we will find the best solution even for tricky challenges.

Speed

Time plays an important role for the majority of our customers when procuring silicone seals. They therefore expect a fast, transparent and informative quotation. Here, too, you can rely on KREMER. Our employees know that your delivery and production processes must continue to run smoothly and therefore work very efficiently and flexibly:

As soon as your enquiry has reached us with all the requirements and specifications or you have spoken to our expert advisors in person, you will usually receive a customised quotation for your silicone seals within 24 hours. You can also expect speed when it comes to our delivery times. As soon as all the parameters for silicone seals are known, we can give you the shortest possible delivery time.

Quality for the highest demands

Especially when it comes to customised silicone seals rather than standard parts, the strictest criteria should apply to their quality and processing. After all, process reliability and product quality often depend on the perfect functioning of silicone seals.

We know the high requirements and the criteria that matter and therefore make no compromises when it comes to the quality of our silicone seals. Not only are we ISO 9001:2015 certified, we also apply the strictest standards when selecting our suppliers. This applies not only to quality, but also to ecological and ethical aspects.

Numbers – Data – Facts

Seals division

Number of seals delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Enquiry for silicone seals

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.

It all depends on the dimensions!

The KREMER calculation programmes allow you to calculate the parameters of your application quickly and precisely. Because O-rings, moulded parts or rubber profiles can only function optimally if the dimensions are correct. With just a few clicks, you can carry out installation and tolerance calculations with the KREMER calculation programmes.

Further information

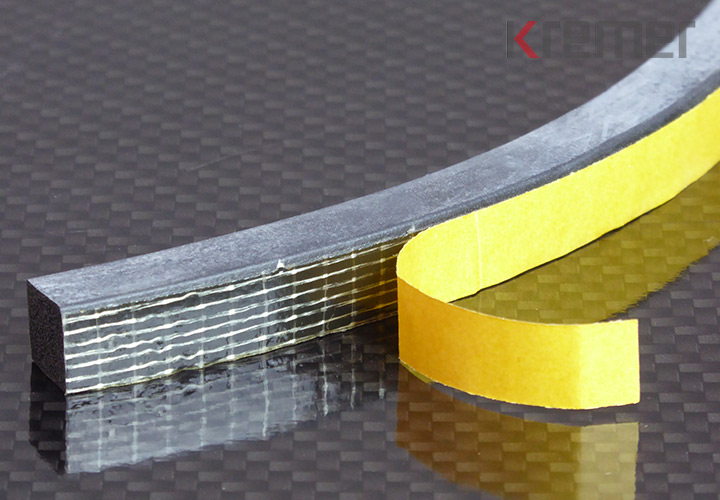

The use of self-adhesive film for elastomer products can be helpful for the user for several reasons. Self-adhesive gaskets are used, for example, for overhead installation of a gasket or to prevent loss during transport of pre-assembled components.

When gaskets, especially profile gaskets with self-adhesive film, are used as an assembly aid for installation, this means that the self-adhesive film has no influence on the function of the gasket after installation.

Self-adhesive stamped gaskets on film are a convenient solution that makes installation easier and safer. If the adhesive film is to have a function other than that of a self-adhesive film for installation purposes, this must be explicitly stated in the enquiry. Our product advisors will carefully check the information on the intended use and include it in the offer according to the possibilities.

In addition to the proper processing and handling of the self-adhesive film in the seal manufacturer's production facility, the storage of the finished elastomer products at the customer's premises plays a decisive role in the durability of the self-adhesive elastomer and silicone products.

The right processing

- Ensure sufficient and even contact pressure.

- Processing tools (including hands) must be free of release agent.

- In the case of extreme loads on bonded joints, it should be noted that the maximum adhesive strength is only reached after approx. 24 hours.

- Avoid permanent tension on the bond.

Underground:

- Do not apply to surfaces containing silicones, paraffins or waxes.

- Do not use paints with adhesion-reducing additives.

- Ensure freedom from dust.

- Ensure freedom from plasticisers.

- Ensure dry surfaces.

- Cover as smooth, closed surfaces as possible.

- Exclude chemical reactions of the surfaces.

Temperatur:

- The optimum bonding temperature is between 20 and 30°C in dry rooms.

- If possible, do not work below 10°C.

- Storage temperature at 18°C and approx. 55% relative humidity.

Influences that impair the adhesive strength of the self-adhesive film:

- High humidity, grease, oil, dust and/or dirt on the surfaces of the parts to be bonded.

- Plasticiser migration.

- Improper storage (deviating from DIN 7716).

Storage and shelf life

As a general rule, only a limited shelf life can be assumed for self-adhesive seals. It is possible that the shelf life of the film is shorter than the warranty period of 12 months for self-adhesive products. It is therefore particularly important that the storage and processing instructions are observed. We recommend that self-adhesive products are processed within six months.

Warranty conditions "Self-adhesive products"

The product must be processed within six months of delivery, taking into account the above-mentioned storage temperature, humidity and processing instructions. No liability/warranty can be accepted for products processed at a later date.