Profile seals: a wide range of applications

In a wide range of variants, customised for you

In a wide range of variants, customised for you

You are looking for a supplier of profile gaskets made of EPDM, silicone, CR or TPE. The possible areas of application are diverse and range from renewable energies and plant, machinery and equipment construction to air conditioning and ventilation technology, container construction, the automotive industry and many others.

If you need medium to large runs - customised - and rely on the highest quality directly from the manufacturer, then contact KREMER! We supply you with endless extruded profile gaskets as

- Hollow chamber profiles,

- Hose profiles,

- solid solid rubber profiles or sponge rubber profiles,

- U and D profile seals,

- Lip seals,

- Square profile gaskets,

- Goods by the metre, profile sections, ready-made rings and frames

and numerous other variants. The flexibility in terms of possible geometries, shapes and material combinations is incredibly high. In addition to single-component profile gaskets, we also offer multi-component profile gaskets - both as classic hard/soft rubber profiles and profiles combining solid rubber profiles and sponge rubber geometry components. For demanding applications, we can also flock, coat or equip your sealing profile with hot-melt adhesive or self-adhesive film. There are virtually no limits to the variety.

Whether you want to use rubber profile seals

- as edge protection,

- for thermal insulation,

- for noise protection,

- as an antique resin profile in automotive engineering or

- in other areas of application

– contact us! As a specialist in customised profile gaskets, we are able to supply you with the exact variant for your application. And with the help of our tolerance calculator, you can determine the correct tolerance specifications for your sealing profile with just a few clicks.

Dealing technology is as versatile as the requirements. You can rely on the wealth of knowledge of our sealing experts - they can draw on a wealth of experience that we are happy to pass on to you. So let's talk about the application in which you would like to use profile seals. We will be happy to provide you with a customised quotation!

Customised profile gaskets? That's why KREMER!

Three things you can expect from us as a supplier of profile seals:

Sound expertise

Both our customers, who already know exactly what they need for a profile seal, and those who want professional support in their selection, appreciate the expertise of the KREMER team. Our employees familiarise themselves with your processes and know all the details and subtleties that are important in the field of sealing profiles.

Based on our many years of experience in sealing technology, we are therefore able to offer you the right solution, even for difficult challenges. This combination of service and expertise has proven itself time and again throughout KREMER's 60-year company history.

Fast quotation, short delivery times

Fast, transparent and informative quotations are another of KREMER's strengths. Time is of the essence for most of our customers, as important production and delivery processes in their companies depend on the rapid availability of profile seals.

This is why our employees work efficiently and flexibly: as soon as we receive your enquiry with all the requirements and parameters or you have spoken to our specialist advisors in person, we will usually provide you with a customised quotation within 24 hours. We aim for a short delivery time for all profile sealing orders once all relevant data is available.

Product quality for the highest demands

With profile gaskets in particular, where there are so many geometry and material variants, it is important that they are perfectly matched to the respective area of application. Your demands on quality are therefore correspondingly high - not least because of the role of seals in terms of process reliability and product quality in your company.

To ensure that we can meet your strict specifications and requirements, we only consider suppliers who fulfil all these requirements 100%. Not only are we ISO 9001:2015 certified, but we also pay attention to ecological and ethical criteria when selecting our suppliers.

Figures - Data - Facts

Seals division (as at 2022)

Number of profile seals supplied in 2020

Realised drawing parts

Number of active customers in 2022

Sales share of largest customer in %

Contact

Enquiry profile seals

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Application examples for profile seals

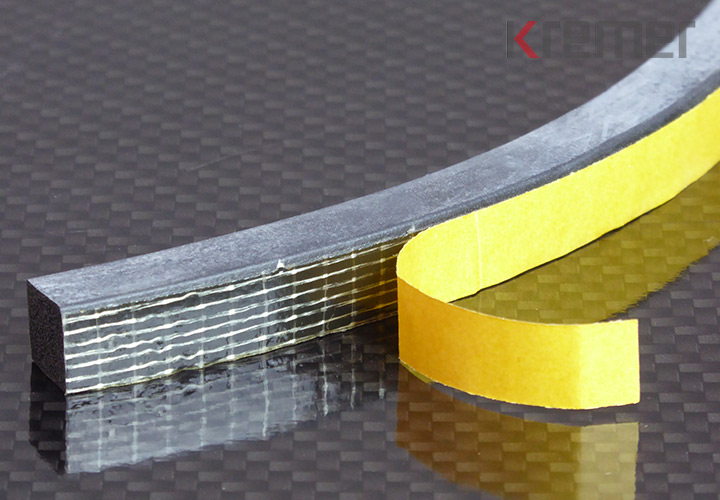

Our customer was looking for a self-adhesive profile seal that could be easily compressed and had a material surface with a low coefficient of sliding friction. All tests with competitor products failed in advance because the standard profiles could not withstand a relative movement in the longitudinal direction when the door latched without damage.

To fulfil the customer's requirements

- glueable,

- compressible and

- a material with a sliding surface

the KREMER team has chosen the following composition:

An EPDM cellular rubber sheet on one side with a Self-adhesive film (the picture shows the removable yellow protective paper of the self-adhesive film). The opposite contact side to the door was laminated with a PET film.

Cellular material can be compressed with varying degrees of ease depending on its density, whereas solid rubber material can only be displaced under pressure or the selected profile geometry can be deformed.

No special moulds are required to apply an adhesive film or PET film. What's more, we were able to dispense with the higher machine costs of a 2-component extrusion system. Advantages that are particularly convincing for small to medium quantities.

If normal operating conditions - standard room temperatures, normal humidity - are given, TPE is a good alternative as a material for profiles toEPDM. The advantages lie primarily in the

- Pricing,

- the mechanically lower processing effort and

- the implementation of the customer's specific colour specifications.

The customer asked us for support in designing a coloured profile to be installed on a polycarbonate urinal bowl.

Due to its design, the plastic basin has different wall thicknesses. Another requirement was that different bending radii of the profile to be attached had to be taken into account in the design. In order to reduce assembly times on site, the customer wanted to be able to attach the TPE profile before the pool was mounted on the wall. The profile was also not allowed to cause stress cracking in the polycarbonate.

To avoid stress cracking in polycarbonate, special attention must be paid to formulation components such as plasticisers. The TPE material we chose proved to be unproblematic here. The use of a hot-melt adhesive was the perfect solution for the task in order to be able to pre-assemble the profile without loss before fixing it to the tiling. The use of a classic clamping profile was not necessary, giving the profile a more elegant appearance.

We determined the optimum profile cross-section quickly and efficiently using rapid prototyping. With just a few changes to the profile cross-section, we were able to optimise the behaviour of the profile during bending. This ensured that the sealing lip of the profile was in perfect contact with the tile surface.

Seals in greenhouses are exposed to many unfavourable conditions. They are exposed to high humidity and ozone, they have to be very robust and allow a maximum amount of light to pass through. We were commissioned by our customer to test the resistance to stress cracking.

Procedure:

Testing of three elastomer compounds. These elastomer compounds were selected according to whether they are suitable for the application of a static seal in greenhouse construction.

PMMA bending rods clamped horizontally on one side are brought into contact with the elastomer products to be tested (profiles/elastomer sheet material) on the upper side of the test specimens over as large an area as possible. A defined weight is attached to the other end of the test specimen. This creates a tensile stress of 30 MPa at the clamping point.

The stress decreases linearly with increasing distance from the clamping point until it reaches zero. The test specimens and the elastomer samples attached to them are subjected to tensile stress for 24 hours at 50°C.

At the end of the test period, the elastomer samples are removed and the distance from the clamping point at which the first stress crack can be recognised as a so-called silverfish is measured. Due to the linear drop in stress, the distance from the clamping point can be equated with the greatest stress that caused a crack in the transparent PMMA plastic in the first place - the so-called limit stress.

Limit values of >15 MPa provide a relatively high degree of certainty that the elastomeric material of a static seal will not cause stress cracking in contact with PMMA.

The formulation of the elastomer compound, with which a limit stress of 18 MPA could be achieved, was used as the basis for the sampling of the profile seal.

Important!

If the product compositions of the two sealing partners in contact are changed or if they change due to ageing processes and the effects of the weather, deviations from the test result may occur.

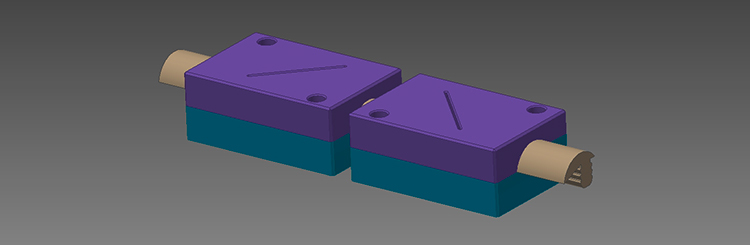

Cutting device TPE profile

Product requirement: A TPE profile with very thin sealing lips, 15 mm wide and 12 mm high, must be mitred (45° cut) in order to be able to glue a rectangular profile sealing frame.

Special feature: The cross-section of the profile seal has a thin lip. The TPE material used is also very soft. This requires particular care and precision when cutting. There is a risk that the profile geometry will be deformed during cutting and that the resulting mitre cut will not be suitable for bonding.

The solution: The KREMER technicians designed and realised a cutting device using 3D printing within just a few hours. We present the design to you using a CAD model.

The printed cutting device guides the thin-lipped profile and aligns it. The sealing profile is located at the point where the cutting blade, which is turned at a 45° angle, plunges in. The profile is thus supported from all sides. It is in a stable position. This prevents the thin sealing lip from turning over or becoming deformed.

The fabric is cut by the metre by machine and glued to the frame by hand by experienced workers.

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.

It all depends on the dimensions!

The KREMER calculation programmes allow you to calculate the parameters of your application quickly and precisely. Because O-rings, moulded parts or rubber profiles can only function optimally if the dimensions are correct. With just a few clicks, you can carry out installation and tolerance calculations with the KREMER calculation programmes.

Further information

The use of self-adhesive film for elastomer products can be helpful for the user for several reasons. Self-adhesive seals are used, for example, for overhead installation of a seal or to prevent loss during transport of pre-assembled components.

If gaskets, especially profile gaskets with self-adhesive film, are used as an assembly aid for installation, this means that the self-adhesive film has no influence on the function of the gasket after installation.

Punched gaskets self-adhesive on film are a convenient solution that makes installation easier and safer. If the adhesive film is to have a function other than that of a self-adhesive film for mounting purposes, this must be explicitly stated in the enquiry. Our product advisors will carefully check the information about the intended use and include it in the quotation according to the possibilities.

In addition to the proper processing and handling of the self-adhesive film in the seal manufacturer's production facility, the storage of the elastomer finished products at the customer's premises plays a decisive role in the durability of the self-adhesive elastomer and silicone products.

The right processing

- Ensure sufficient and even contact pressure.

- Processing tools (including hands) must be free of release agent.

- In the case of extreme loads on bonded joints, it should be noted that the maximum adhesive strength is only reached after approx. 24 hours.

- Avoid permanent tension on the bond.

Underground:

- Do not apply to surfaces containing silicones, paraffins or waxes.

- Do not use paints with adhesion-reducing additives.

- Ensure freedom from dust.

- Ensure freedom from plasticisers.

- Ensure dry surfaces.

- Cover as smooth, closed surfaces as possible.

- Exclude chemical reactions of the surfaces.

Temperatur:

- The optimum bonding temperature is between 20 and 30°C in dry rooms.

- If possible, do not work below 10°C.

- Storage temperature at 18°C and approx. 55% relative humidity.

Influences that impair the adhesive strength of the self-adhesive film:

- High humidity, grease, oil, dust and/or dirt on the surfaces of the parts to be bonded.

- Plasticiser migration.

- Improper storage (deviating from DIN 7716).

Storage and shelf life

As a general rule, only a limited shelf life can be assumed for self-adhesive seals. The shelf life of the film may be shorter than the warranty period of 12 months for self-adhesive products. It is therefore particularly important that the storage and processing instructions are observed. We recommend processing the self-adhesive products within six months.n.

Warranty conditions "Self-adhesive products"

The product must be processed within six months of delivery, taking into account the above-mentioned storage temperature, humidity and processing instructions. No liability/warranty can be accepted for products processed at a later date.

Download product information

Download Infokarte "Profildichtungen"

to the download area "Infokarten"