Seals made from FFKM Krevolast®

What is FFKM?

Krevolast® is KREMER's own FFKM brand and a particularly economical solution when the FFKM material is required for stamped Seals or as Flat gasket is to be used. Krevolast® combines outstanding properties:

- Very good resistance at low and very high temperatures between -40°C and +330°C depending on Krevolast®

- Particularly high compression and recovery properties (explosion decompression resistance)

- Broad chemical resistance, e.g. acids, alkalis, other aggressive chemicals

- Hot water and vapour resistance

- Good compression set

- Fulfilment of high safety and cleanliness requirements

We offer this material in numerous different grades (see material data sheets below) so that you can select the right grade for your application. Thanks to its positive properties and the variety of grades, Krevolast® can be used for a wide range of applications. The high-performance fluoroelastomer FFKM is a high-performance elastomer with excellent chemical properties - similar to those of PTFE - and the elastic properties of FPM.

Seals made of FFKM are primarily used in the following areas:

- chemical process industry,

- Food industry,

- Vacuum technology,

- semiconductor industry,

- Raffinerien,

- Production of biofuels,

- Cosmetics and pharmaceuticals,

- Pumps,

- Drilling tools,

- Ventile,

- Reactors

- high-purity applications.

Properties of FFKM at a glance

Existing

-

Shore Range

60 to 90 -

Temperature Range

-15°C to +240°C -

Oil Grease

Feature available -

Petrol

Feature available -

Diesel

Feature available -

Ozone

Feature available -

Weather

Feature available -

Cleanser

Feature available -

Sea Water

Feature available

Optional

-

Extreme Temperature

-40°C to +330°C on request -

Gas

on request -

Food

on request (FDA compliant) -

Steam

on request

Numbers – Data – Facts

Seals division

Number of seals delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Enquiry for FFKM seals

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

You can download the specifications for the desired application. You will find a list of the physical, thermal and mechanical properties as well as the resistances in our material data sheets. If you have any questions about Krevolast® and its processing, please call our technical advisors or let us convince you with figures and send us your enquiry directly. Anfrage.

Further information

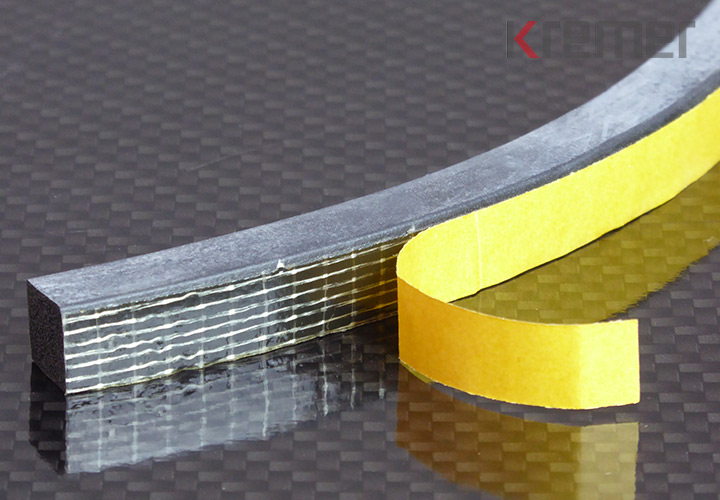

The use of self-adhesive film for elastomer products can be helpful for the user for several reasons. Self-adhesive seals are used, for example, for overhead installation of a seal or to prevent loss during transport of pre-assembled seals. Assemblies used.

When Seals, especially Profile seals with self-adhesive film are used as an assembly aid for installation, this means that the self-adhesive film has no influence on the function of the seal after installation.

Punched gaskets self-adhesive on film are a convenient solution that makes installation easier and safer. If the adhesive film is to have a function other than that of a self-adhesive film for mounting purposes, this must be explicitly stated in the enquiry. Our product advisors will carefully check the information about the intended use and include it in the quotation according to the possibilities.

In addition to the proper processing and handling of the self-adhesive film in the seal manufacturer's production facility, the storage of the elastomer finished products at the customer's premises plays a decisive role in the durability of the self-adhesive elastomer and silicone products.

The right processing

- Ensure sufficient and even contact pressure.

- Processing tools (including hands) must be free of release agent.

- In the case of extreme loads on bonded joints, it should be noted that the maximum adhesive strength is only reached after approx. 24 hours.

- Avoid permanent tension on the bond.

Underground:

- Do not apply to surfaces containing silicones, paraffins or waxes.

- Do not use paints with adhesion-reducing additives.

- Ensure freedom from dust.

- Ensure freedom from plasticisers.

- Ensure dry surfaces.

- Cover as smooth, closed surfaces as possible.

- Exclude chemical reactions of the surfaces.

Temperatur:

- The optimum bonding temperature is between 20 and 30°C in dry rooms.

- If possible, do not work below 10°C.

- Storage temperature at 18°C and approx. 55% relative humidity.

Influences that impair the adhesive strength of the self-adhesive film:

- High humidity, grease, oil, dust and/or dirt on the surfaces of the parts to be bonded.

- Plasticiser migration.

- Improper storage (deviating from DIN 7716).

Storage and shelf life

As a general rule, the following applies to self-adhesive Seals only a limited shelf life can be assumed. The shelf life of the film may be shorter than the warranty period of 12 months for self-adhesive products. It is therefore particularly important that the storage and processing instructions are observed. We recommend that self-adhesive products are processed within six months.

Warranty conditions "Self-adhesive products"

The product must be processed within six months of delivery, taking into account the above-mentioned storage temperature, humidity and processing instructions. No liability/warranty can be accepted for products processed at a later date.

Download product information

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.