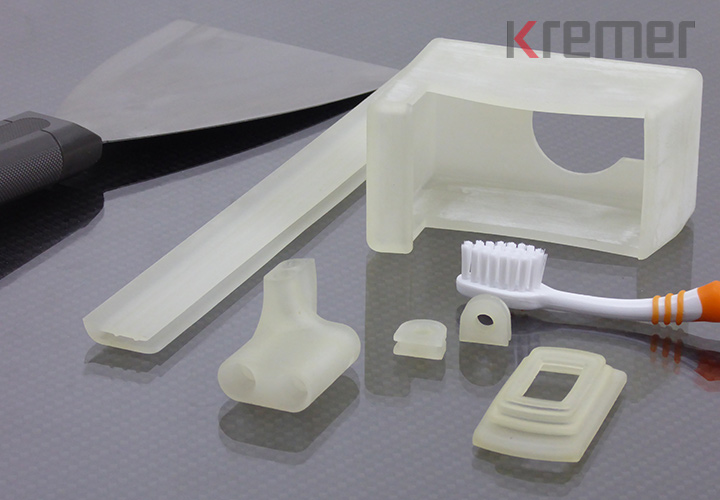

Moulded parts/injection-moulded parts made of silicone

Made to measure, precisely tailored to your application

Made to measure, precisely tailored to your application

Are you looking for a supplier of silicone moulded parts for applications in the electrical appliance, household appliance and Automobilindustrie obut which you want to use in contact with food? Silicone moulded parts are a speciality at KREMER. We have a large repertoire of experience in a wide range of applications for silicone moulded parts, including

- Housing seals for engine control units,

- Plug seals for cable harnesses and wiring systems,

- Shelves for irons,

- Seals for vacuum jugs,

- Plug-in connections for oven controller,

- Hot water-conducting riser pipe connectors for beverage machines

... and countless other variants. The optimum silicone material and production method for manufacturing your moulded parts depends on the area of application and the specifications they have to meet.

As standard, silicone injection moulded parts (HTV, LSR, MVQ, VMQ) are extremely flexible at low temperatures, extremely resistant to heat and oxidation and ideal for static applications. If greater resistance to aromatic mineral oils (e.g. ASTM oil no. 3), fuels and some hydrocarbons is required, we recommend silicone moulded parts made of fluorosilicone. HTV silicone rubbers are also available for moulded parts that have been approved for use with food (FDA, BfR), drinking water (KTW, W270, WRAS) and gas (DVGW, EN 549).

Moulded silicone parts made of liquid silicone, on the other hand, are the ideal choice when similar material properties to HTV silicone are required, but higher demands are placed on the tear resistance and elongation at break of the moulded part.

The variety of materials and processing methods is so great that it is always best to contact KREMER right from the start.

Let us talk about your silicone moulded parts and determine the optimum production variant and the right material for you. As soon as all the parameters are known, we will prepare a customised offer for you!

Overview of silicone properties

Existing

-

Shore Range

20 to 80 -

Temperature Range

-55°C to +200°C -

Ozone

Feature available -

Weather

Feature available -

Food

Feature available -

Sea Water

Feature available

Optional

-

Extreme Temperature

-90°C to +250°C on request -

Steam

on request

Printed silicone parts

We can provide you with the CAD data for the desired silicone moulded part within a few hours and without tooling costs. 3D printed prototypes made of soft and flexible silicone-like elastomer material for your development and design departments.

Silicone moulded parts? That's why KREMER!

Three good reasons why we are your ideal supplier for silicone moulded parts:

Always the best option for you

When it comes to silicone moulded parts, you are dependent on the production facilities available to many suppliers - there is not always the most flexible and cost-effective option for your needs. At KREMER, we have access to a broad network of manufacturers and suppliers, which makes us completely independent of specific manufacturing processes and procurement sources.

This enables us to compare and weigh up all production options for you and at the same time bring in the product specialisation of our partner companies and offer you the most flexible and economically attractive option. At KREMER, you benefit from this clear cost advantage over other suppliers both in the production of individual silicone moulded parts and in large series.

High level of expertise and moulded part quality

Silicone moulded parts have to meet numerous requirements and specifications on which the product quality depends. At KREMER, we are familiar with the strict requirements - from the experience and tricky challenges that we have gained from working with customers from countless sectors and industries during our more than 60 years of company history.

With this know-how, we are in a position to advise you from the planning stage right through to the production of your silicone moulded parts. Of course, you can also rely on KREMER when it comes to quality. We only use suppliers and partner companies that meet your high standards. We make our choice according to qualitative as well as ecological and ethical aspects.

Fast quotation, short delivery times

Time pressure plays a major role for the majority of our customers when it comes to procuring silicone moulded parts. Our team works efficiently and flexibly for you: as soon as we receive your moulded part enquiry with all the details and specifications or you have spoken to our specialist advisors in person, we will usually provide you with a meaningful, transparent and individual quotation within 24 hours! You will also be impressed by our short delivery times: as soon as all the parameters for silicone moulded parts are known, we can provide you with the shortest possible delivery time.

Numbers – Data – Facts

Information from KREMER

Number of molded parts delivered

Realized drawing parts

Number of active customers

Sales share of largest customer in %

Contact

Enquiry for silicone moulded parts

Sales to commercial customers only

Note on mandatory fields and data protection

Mandatory fields are marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and answering your request. Information on data processing can be found in the privacy policy.

Do you have any questions about our products?

Whether O-rings, seals, moulded parts or materials - in the FAQ section you will find answers and lots of further information about the KREMER product range.

It all depends on the dimensions!

The KREMER calculation programmes allow you to calculate the parameters of your application quickly and precisely. Because O-rings, moulded parts or rubber profiles can only function optimally if the dimensions are correct. With just a few clicks, you can carry out installation and tolerance calculations with the KREMER calculation programmes.