Tear resistance (DIN 53507 and 53515)

Tear propagation resistance describes how well an already scored or cut elastomer can resist further tearing. It refers not to the initial tear (tensile strength), but to the force required to propagate an existing cut further through the material.

Tear propagation resistance is typically specified in N/mm – as force per unit length of crack or material thickness. The higher the value, the less sensitive a rubber is to notches, cuts, or damage during operation.

Tear propagation resistance vs. tensile strength

• Tensile strength (tensile strength in elastomers) describes the maximum stress when an undamaged sample tears.

• Tear propagation resistance specifically considers the worst-case scenario: The sample is already scored or cut, and the test examines how easily this tear can propagate further.

For seals, O-rings, profiles, and molded rubber parts, tear propagation resistance is therefore an important parameter for assessing notch sensitivity – for example, in cases of assembly damage, sharp edges, or localized overstretching.

Test methods according to DIN 53507 and DIN 53515

The tear resistance of vulcanizates is measured using a tensile testing machine. Two classic test geometries are:

• Strip test (DIN 53507)

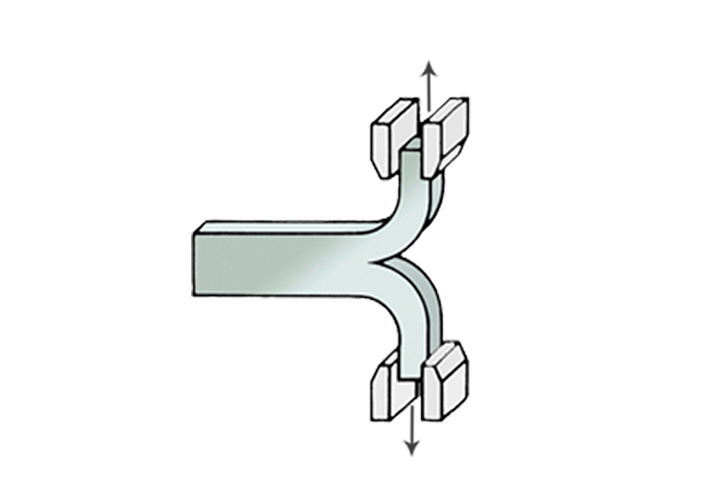

A narrow rubber strip is given a defined pre-slit. In the tensile test, the strip is loaded so that the crack propagates longitudinally. The tear resistance in N/mm is calculated from the required force and the specimen geometry.• Graves angle test (DIN 53515)

The specimen has an angled geometry with a cut slit. In the tensile test, the load is concentrated at the tip of the slit, so that the crack propagates in a controlled manner. Here, too, the required force is related to the relevant crack length.Both methods provide characteristic values that make crack propagation in a pre-damaged elastomer quantifiable. Comparable tests are further developed in newer standards, e.g., in ISO standards for rubber.

Factors Influencing Tear Resistance

Tear resistance depends on, among other things:

• Elastomer type (e.g., NBR, EPDM, VMQ, FKM)

• Degree of crosslinking and crosslinking system (sulfur vs. peroxide)

• Filler system (type and quantity of carbon black, silica, mineral fillers)

• Test temperature and strain rate

• Specimen geometry and crack orientation (anisotropy due to fiber or profile structure)Highly filled, very hard compounds can, for example, exhibit high tensile strength but comparatively lower tear resistance – notches then propagate more easily.

Importance in Sealing Technology

Good tear resistance is particularly important for:

• O-rings and sealing lips that are pulled over threads, edges, or grooves during assembly

• Profile and frame seals that are bent, compressed, or tensioned during installation

• Elastomeric molded parts with thin webs, membranes, or sharp geometric transitions

• Vibration and bearing elements that can be subjected to alternating loads and local overstretchingIn practice, high tear resistance means:

Even if a seal or rubber part sustains small cuts, notches, or cracks, these propagate less quickly through the component. The risk of a sudden tear—and thus seal or component failure—is significantly reduced.

Contact