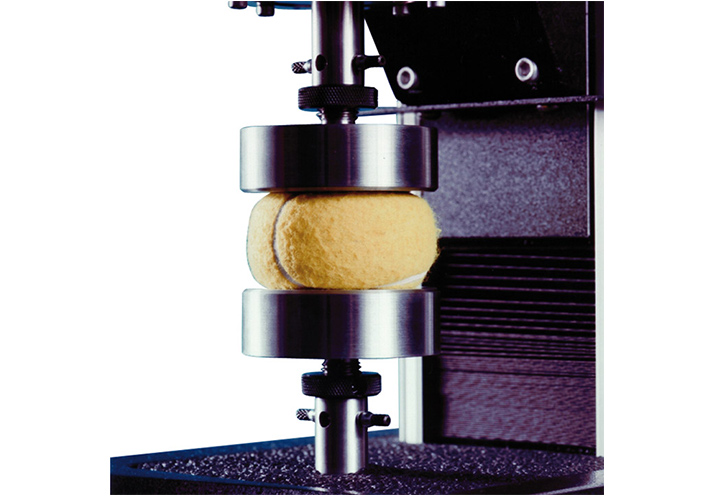

Compression test

The compression test is a mechanical test method used to examine the behaviour of materials under uniaxial compressive stress. In contrast to the tensile test, the specimen is not pulled but compressed. This allows specific properties to be determined that are crucial for components under compressive stress, such as elastomer buffers, moulded rubber parts or seals.

Test setup and procedure

As a rule, a cylindrical compression specimen with a defined initial cross-section and height is clamped between two parallel compression plates. The testing machine applies a steadily increasing compressive force to the specimen. The force and displacement (compression) are recorded continuously.

These measured variables are used to calculate the compressive stress and the corresponding compression, which are then plotted in a stress-strain curve (compressive force-compression curve).

Typical characteristic values from the compression test

Depending on the material and standard, the following characteristic values, among others, can be determined:

- Compression modulus or modulus of elasticity in the compression range

- Compressive strength or permissible compressive stress

- Course of the stress-strain curve (linear-elastic range, flow, compression)

- Creep and settlement behaviour under continuous load

The compression test is particularly relevant for elastomers, rubber and sealing technology: it provides data on the deformation and recovery behaviour of O-rings, profiles, buffer and bearing elements or other moulded parts under pressure. These characteristic values are directly incorporated into the design of

Contact