Blog

Blog article

KREMER's largest waterjet part

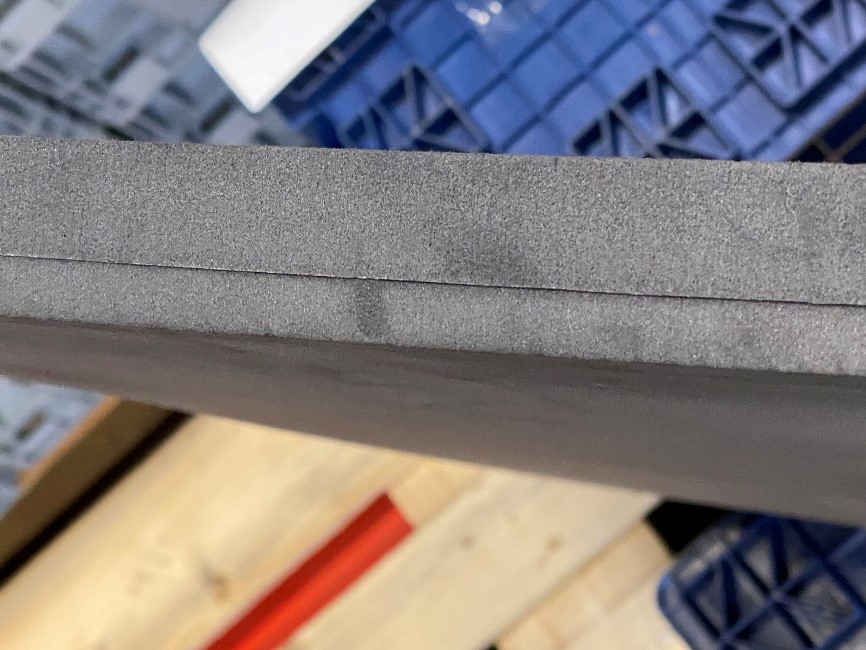

The largest waterjet part to date - large in size, but small in requirements

The water jet-cut PE foam load carrier for an injection moulding company in the automotive supply industry can hold 18 plastic parts. The products to be transported and protected against scratches are subject to visible part requirements. With a size of 780 x 1180 x 30 mm, the load carrier is the largest water jet part manufactured by KREMER (to date), but it is only required in small quantities.

What is called addition in mathematics is called doubling here

The special feature of the water jet part is that it consists of two independently manufactured panels - a 780 x 1180 x 10 mm thick panel as the base part and a second 780 x 1180 x 20 mm thick contour panel with the curved geometry of the product to be transported and protected and with the cut-outs removed. Both panels were then glued together. 10 + 20 became 30; we call this doubling.

This special design from KREMER is easy to load, the products to be transported have a stable hold and can be easily removed from the car manufacturer's assembly line.

All the advantages of the load carrier at a glance:

- High-quality PE foam

- Doubliert

- Transports plastic parts particularly safely

- Water jet part: No tools required during manufacture

- Customised products possible

KREMER - the specialist for customised elastomer and plastic products

KREMER was founded in 1965 and has been part of the REIFF Group since 1995. KREMER focuses on the product groups of seals, O-rings and moulded parts made of rubber, plastic and thermoplastic elastomers. Two-component products, rubber-metal compounds, sponge rubber profiles, rubber profiles and hose rings complete the extensive product range.

Press contact:

Kremer Technology GmbH

Tim Oettmeier

Kinzigstr.

9

63607 Wächtersbach

Phone: 06053 – 61610

E-mail:

tim.oettmeier@kremer-tec.de