Blog

Blog article

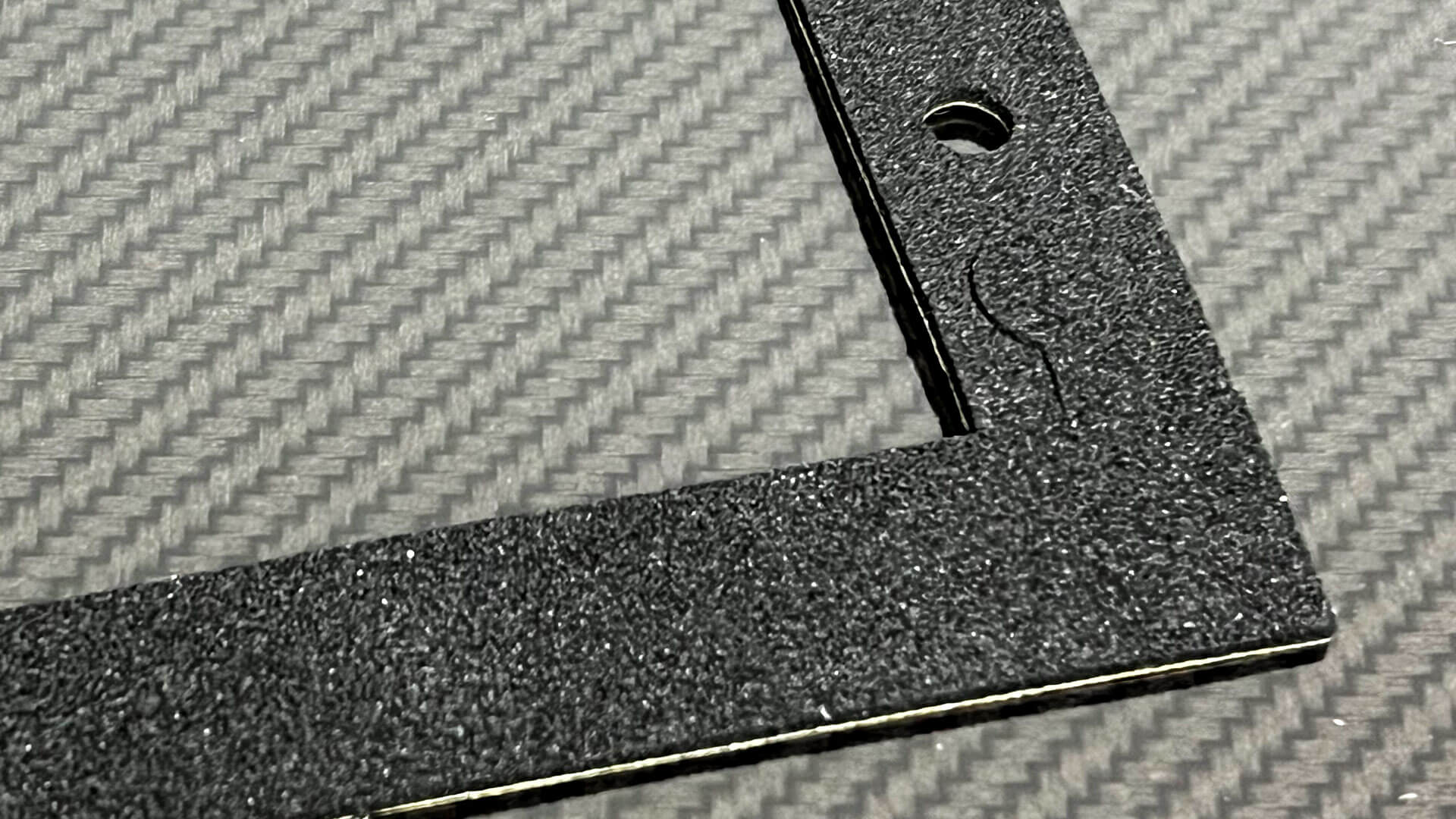

Less³ - Material - Waste - Price: Sealing frame with buttonhole connection

Less material is used in the manufacture of sealing frames with buttonhole joints. This manufacturing method allows you to do something for the environment and save costs.

Seal made from individual segments

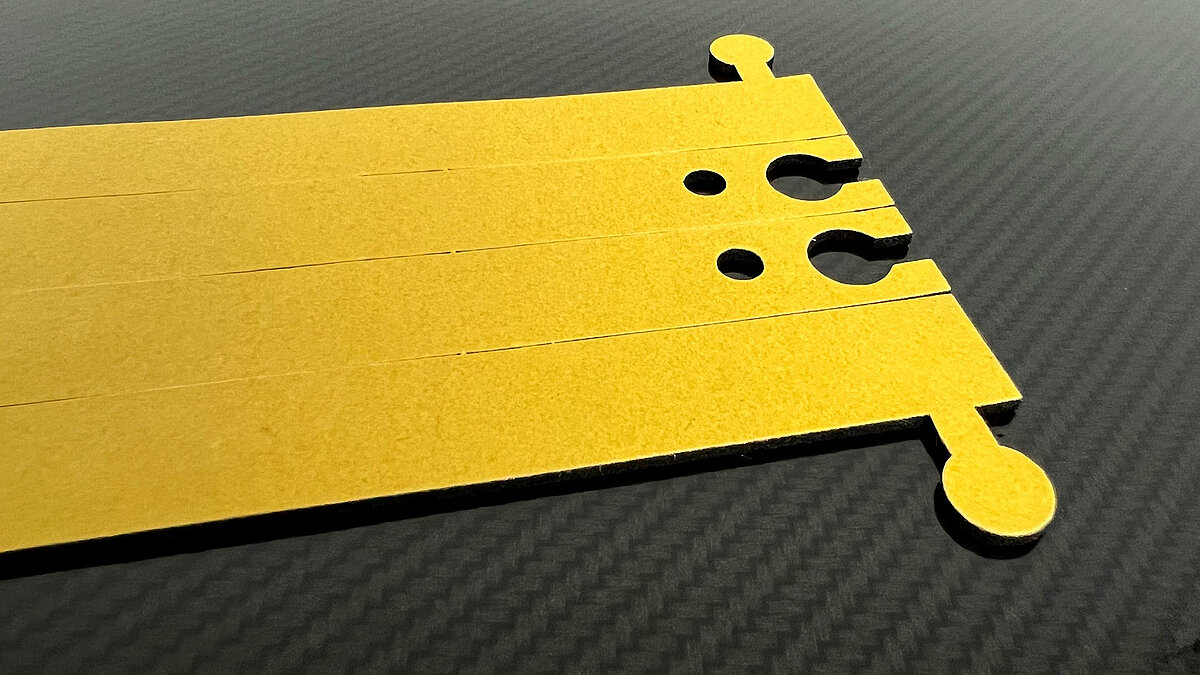

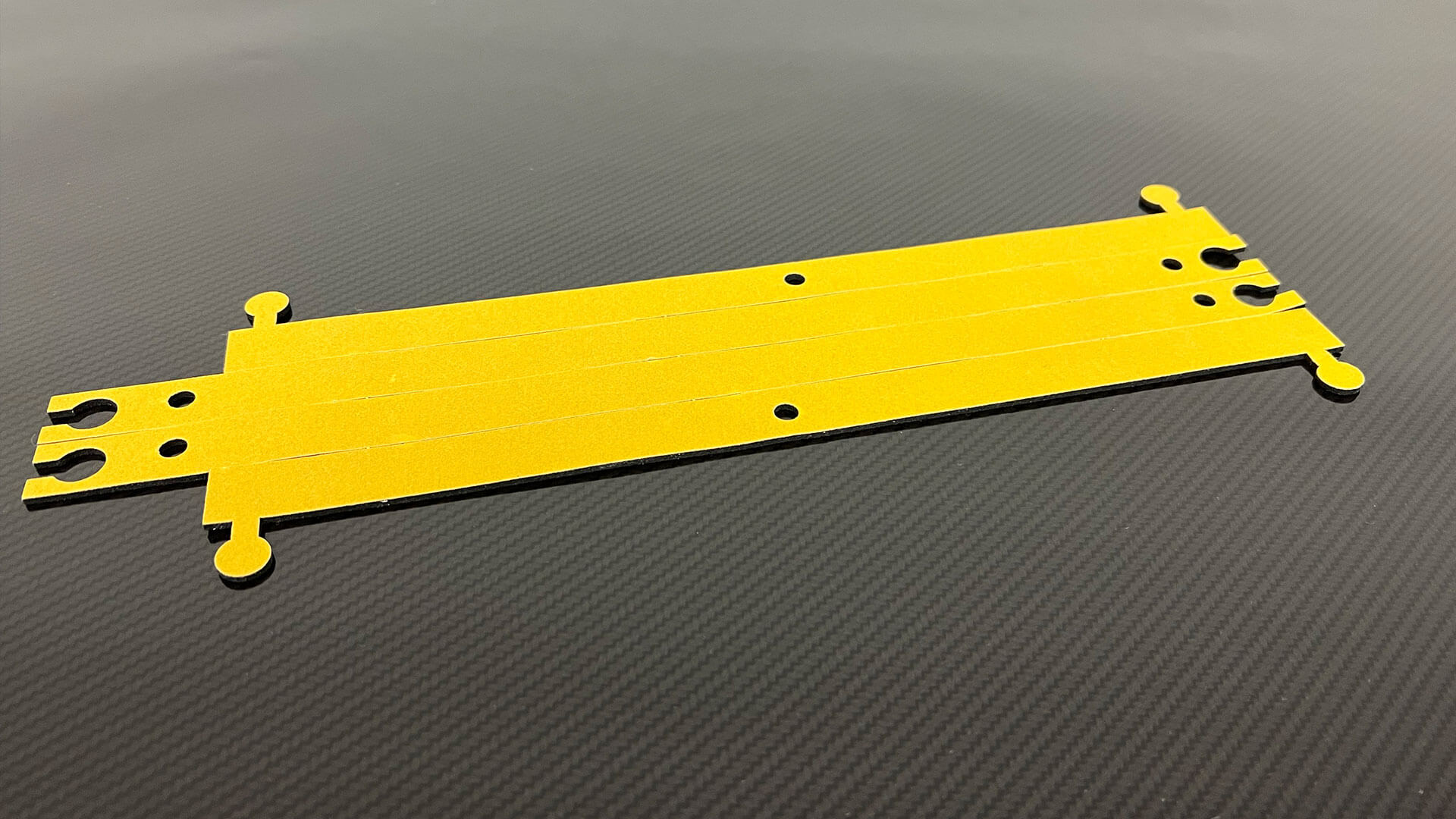

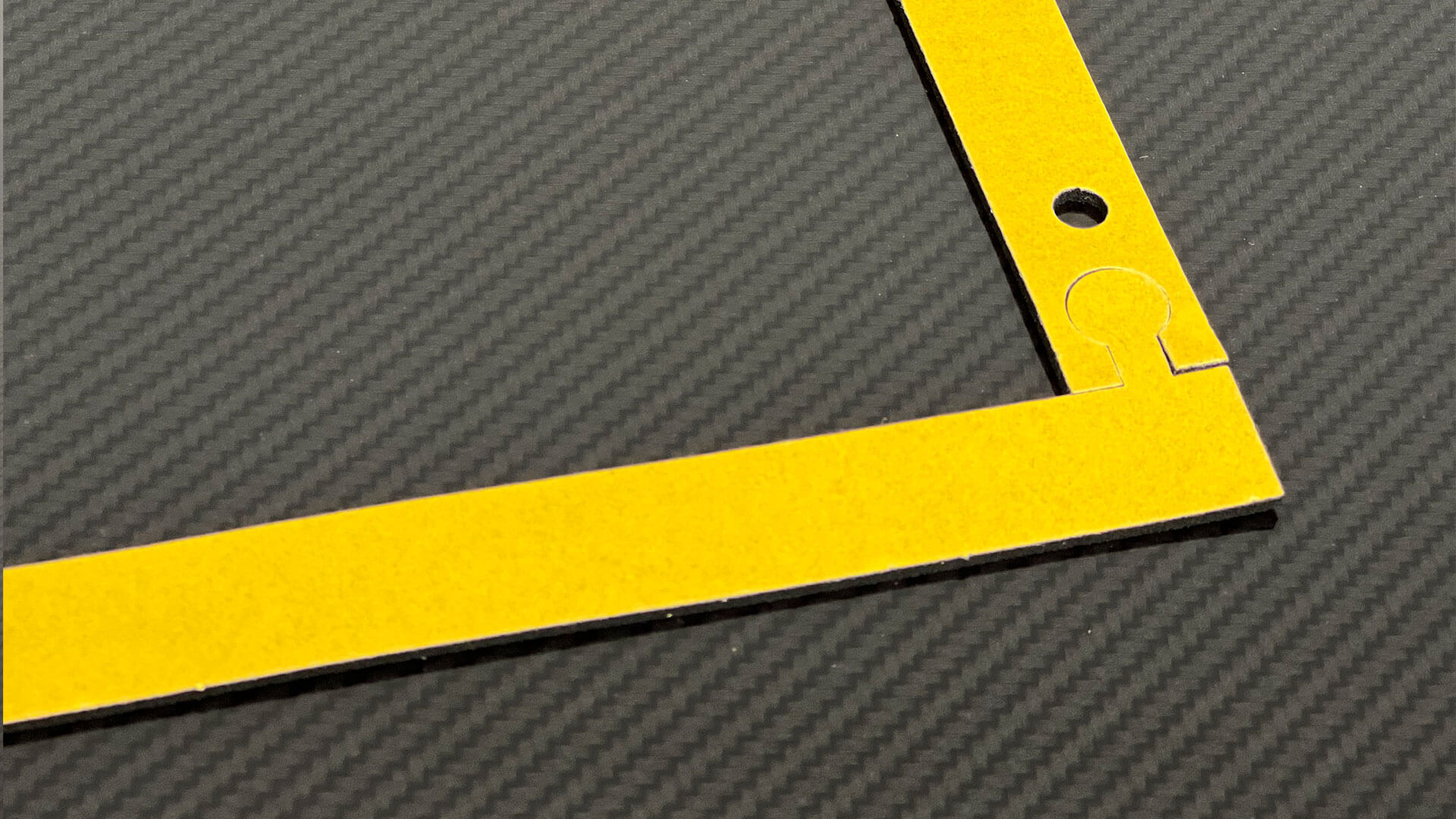

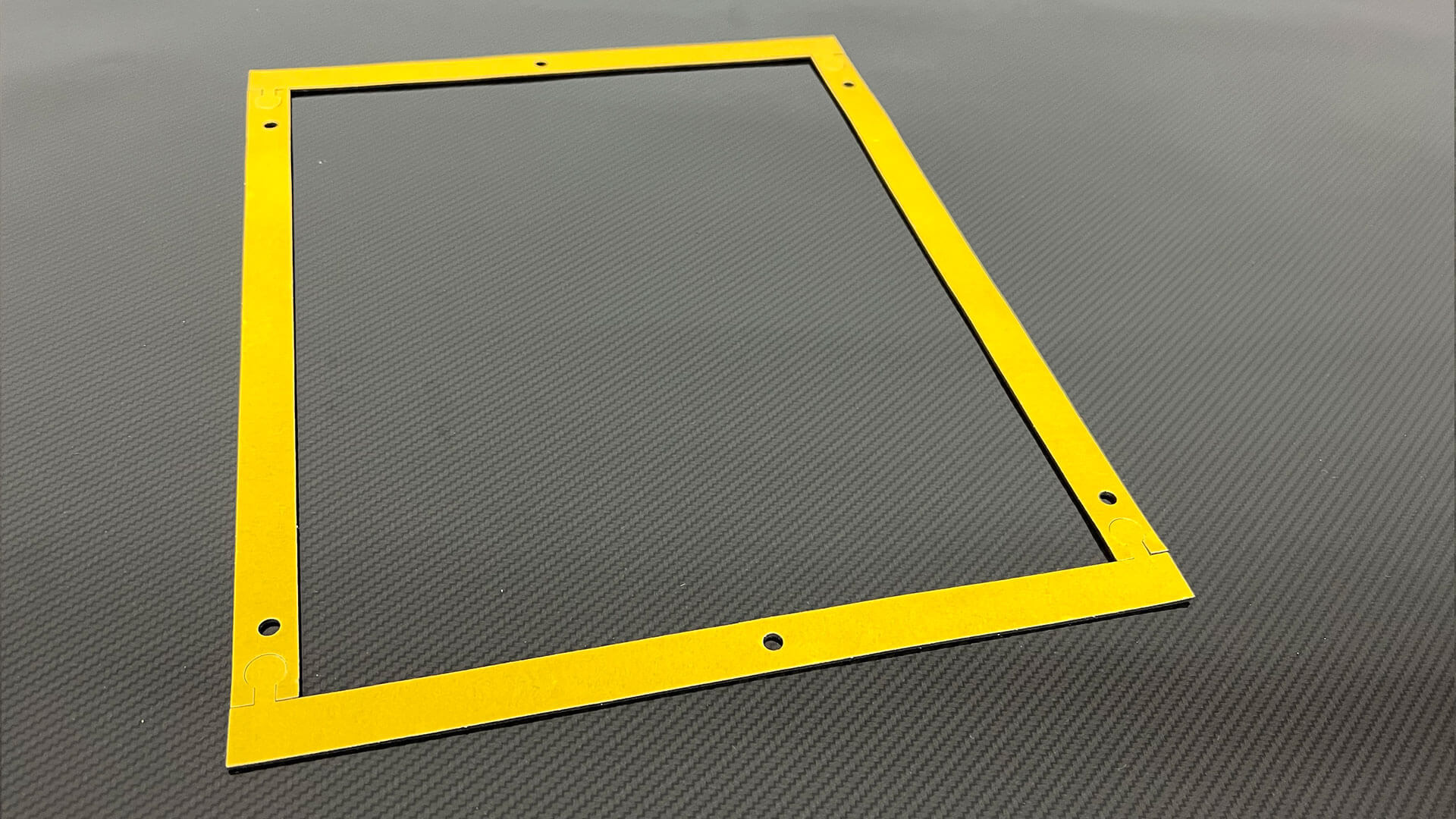

With frames that are manufactured from a single piece, the inner part remains as waste. We avoid this unnecessary waste with the buttonhole joint production method: instead, the gasket is assembled from individual segments. With our sealing frames with buttonhole connection (also known as puzzle connection), we manufacture the individual parts next to each other using a water jet process to save material.

To ensure that the four individual parts remain together as a set, we connect the individual parts with micro bars/holding bars, which can then be easily separated. The frame can then be assembled to the originally desired shape.

Attractive price

This production method, which uses very little material and produces very little waste, not only protects the environment, but also gives you a price advantage that compensates for the somewhat more complex handling.

KREMER - the specialist for customised elastomer and plastic products

KREMER was founded in 1965 and has been part of the REIFF Group since 1995. KREMER focuses on the product groups of seals, O-rings and moulded parts made of rubber, plastic and thermoplastic elastomers. Two-component products, rubber-metal compounds, sponge rubber profiles, rubber profiles and hose rings complete the extensive product range.

Press contact:

Kremer Technology GmbH

Tim Oettmeier

Kinzigstr.

9

63607 Wächtersbach

Phone: 06053 – 61610

E-mail:

tim.oettmeier@kremer-tec.de