Blog

Blog article

Seals: How to avoid stress cracks

Wue to their excellent weather and UV resistance, EPDM and silicone seals are used in many industries: EPDM mainly in façade construction and in the automotive industry, silicone in particular for electronic components and in aviation, ventilation and air conditioning technology.

Regardless of the area of application - seals have to withstand a wide range of influences and often difficult conditions. To ensure that profile seals last as long as possible, the intended use and the materials used are of great importance.

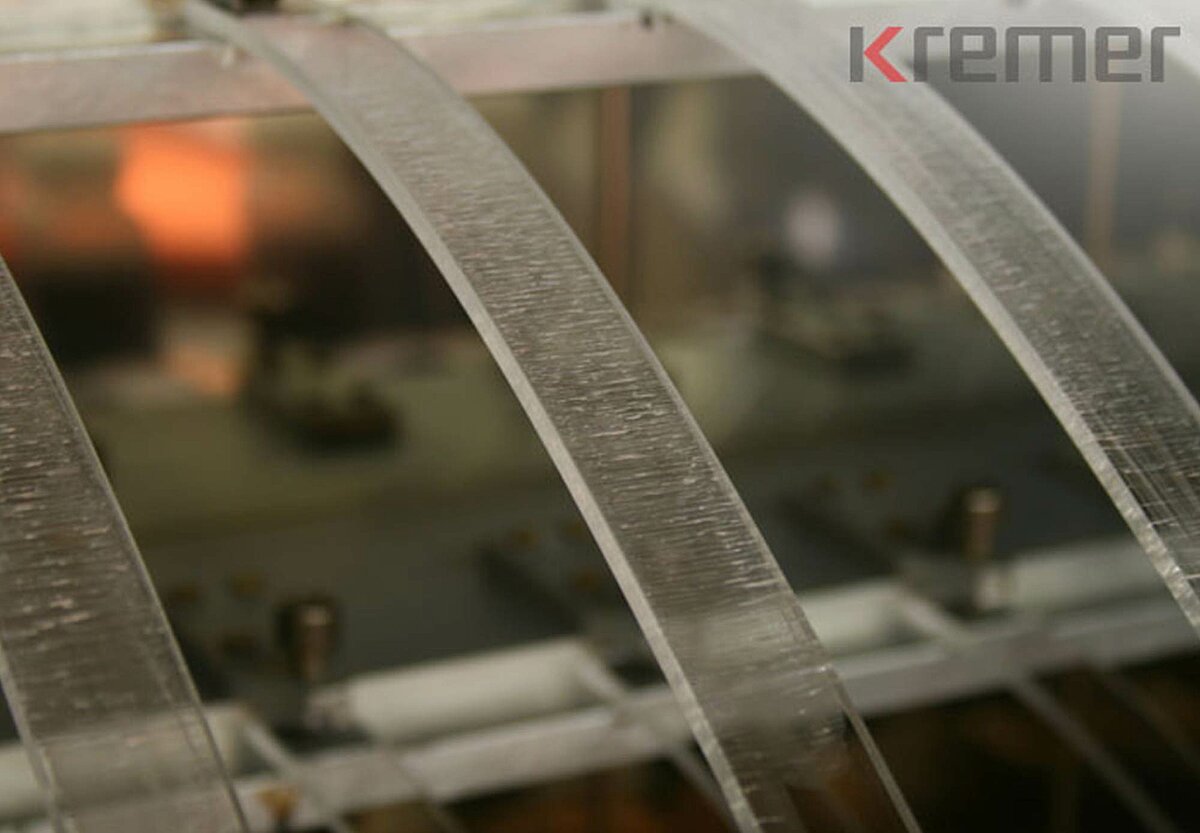

Stress cracks can occur in combination with the transparent plastics PMMA (Plexiglas®) and PC (polycarbonate). In technical jargon, these microcracks are also known as "silverfish". These initially small, barely visible cracks in PMMA or PC panes and hollow chamber profiles can, in the worst case, lead to the failure of a component.

How do stress cracks occur in combination with plastics?

Stress cracks are caused by components of unsuitable rubber compounds. Chemical agents that penetrate the material partner and break up the fine (partially) crystalline molecular structures of the transparent plastic are responsible for the formation of stress cracks. For this reason, the materials used must be tested for stress cracking and found to be suitable for use.

KREMER tests stress cracking resistance

EPDM and silicone gaskets are very resistant. However, if you want to be sure that seals will not cause stress cracks in components made of PMMA and PC, you should indicate the plastic material partner at the enquiry stage. This allows us to check in advance exactly which material is suitable for your application and how it will affect other materials. Experience shows that elastomers with limit stresses of > 15 MPa are suitable for contact with PMMA or PC. You can find out exactly how we proceed when testing stress crack resistance here.

Important factors for elastomer sealing materials:

- Product composition of the "sealing partners" in contact

- Intended use

- Environmental and weather influences

- Ageing processes

KREMER - the specialist for customised elastomer and plastic products

KREMER was founded in 1965 and has been part of the REIFF Group since 1995. KREMER focuses on the product groups of seals, O-rings and moulded parts made of rubber, plastic and thermoplastic elastomers. Two-component products, rubber-metal compounds, sponge rubber profiles, rubber profiles and hose rings complete the extensive product range.

Press contact:

Kremer Technology GmbH

Tim Oettmeier

Kinzigstr.

9

63607 Wächtersbach

Phone: 06053 – 61610

E-mail:

tim.oettmeier@kremer-tec.de