Moulded-In-Place-Gasket (MIPG)

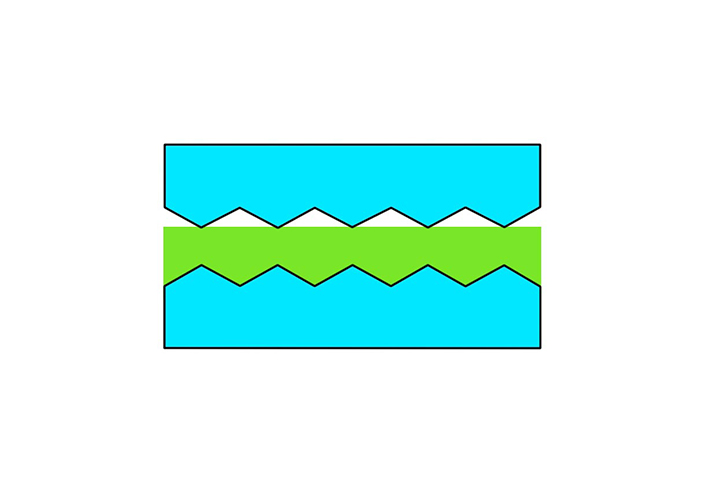

By placing the component in the injection molding or pressing tool, the seal can be given a predetermined sealing geometry. Vulcanization takes place in the tool. The seal adheres to the metal or plastic insert (substrate). The seal is sealed by partial compression.

Materials: High-temperature curing HTV and liquid silicone types, all other elastomers according to suitability

- The seal is injection molded onto the part to be sealed.

- Lost-proof adhesion to the substrate

- Counterform must close exactly

- High technical requirements for components

- Vulcanized molded seal, composite part

Advantages:

- profile geometry variable

- Low compression pressure

- Good sealing at elevations

- and depressions (crescents)

Disadvantages:

- Expensive forms

- Only minor dimensional deviations

- the metal or plastic parts

- Complicated production in injection molding

Possible uses:

- cylinder head cover

- housings of various types

Synonyms: composite seal

Contact