Formed-In-Place Foamed Gasket (FIPFG)

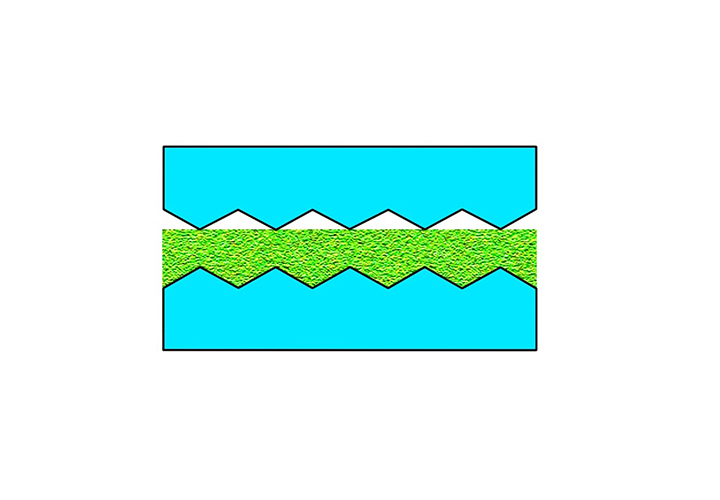

Here, too, a compressible seal is applied to a component in the form of a bead. After vulcanization, the foam seal adheres to the substrate. Installation can take place after vulcanization. The seal is again achieved by partial compression.

Materials: Silicone and PU foams

Procedure:

- Restriction to addition-curing RTV-2 and PU foams

- Components A and B are processed in the dynamic mixer and are usually loaded with gas

- The mixture is applied in flowable or solid form to the parts to be sealed using a robot or coordinate table

- The material foams up on the parts (about 2 to 4 times its volume)

- Reaction slightly exothermic at room temperature

- Depending on the system, fully vulcanized in minutes to hours

- Heat dissipation or heat supply (ambient temperature, heating during mixing, temperature and thermal conductivity of the substrate) influence reaction rate and foam structure

- Sealing must be carried out in groove for flowable systems

Advantages:

- seal compressible

- Low closing forces

- Closed-cell foam

- High tolerances with large dimensional fluctuations

- Automatic application

Disadvantages:

- Not suitable for sealing liquid media such as oils, coolants

- High machine expenditure

- Processing conditions must be adjusted specifically to applications

Possible uses:

- headlight housing

- taillight housing

- intake pipe, intake duct

- ignition cable covers

- housings of various types

- packaging industry

Synonyms: Freely applied silicone or PU foam sealant,Freely applied sealant, Wet installation , Freely applied sealant, Dry installation

Contact