Cured-In-Place-Gasket (CIPG)

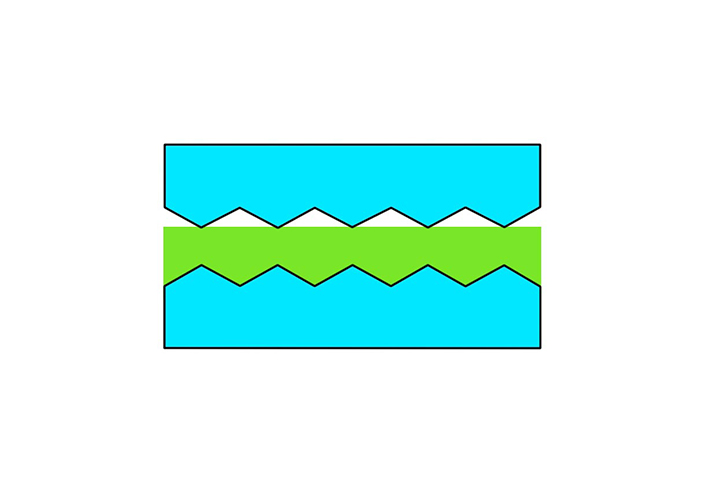

The bead of sealant is applied before vulcanization. After vulcanization, the sealant only adheres to one side of the component. During installation, the seal is achieved by "partial pressing".

Materials: RTV-1 and RTV-2 silicone types, PUR types

The silicone rubber is applied to the part to be sealed in a liquid, pasty state using a mixing and dosing device. The bead is automatically applied with high precision using a robot or coordinate table. The seal is vulcanized in a drying cabinet or IR channel; tempering is usually not necessary.

The seal adheres securely to the part and can be installed as a complete part.Advantages:

• Automatic application of the seal by the system supplier

• Seal adheres to one part, therefore safe from loss

• No tempering of the seal necessary

• Repeated disassembly possible without destroying the seal

• With appropriate dimensioning, sound and noise decoupling possible

• Simple groove constructionDisadvantages:

• Initial mechanics not comparable with synthetic rubbers

• Seal replacement in case of repair

• No special profiling of the seal possiblePossible uses:

• Water pump

• Thermostat housing

• Radiator nozzle

• Radiator seals

• Intake manifolds

• Valve coverOr

• Sealing by pressing in the range between 25 – 35%, compression 25–35%

• Groove width approximately 1.3 to 1.4 times the bead width

• Silicone rubber elastic but not compressible

• Bead cannot be applied round; will be wider than it is high; ratio BH = 1 : 0.8 – 0.6

Contact