Compression set (DIN EN ISO1856)

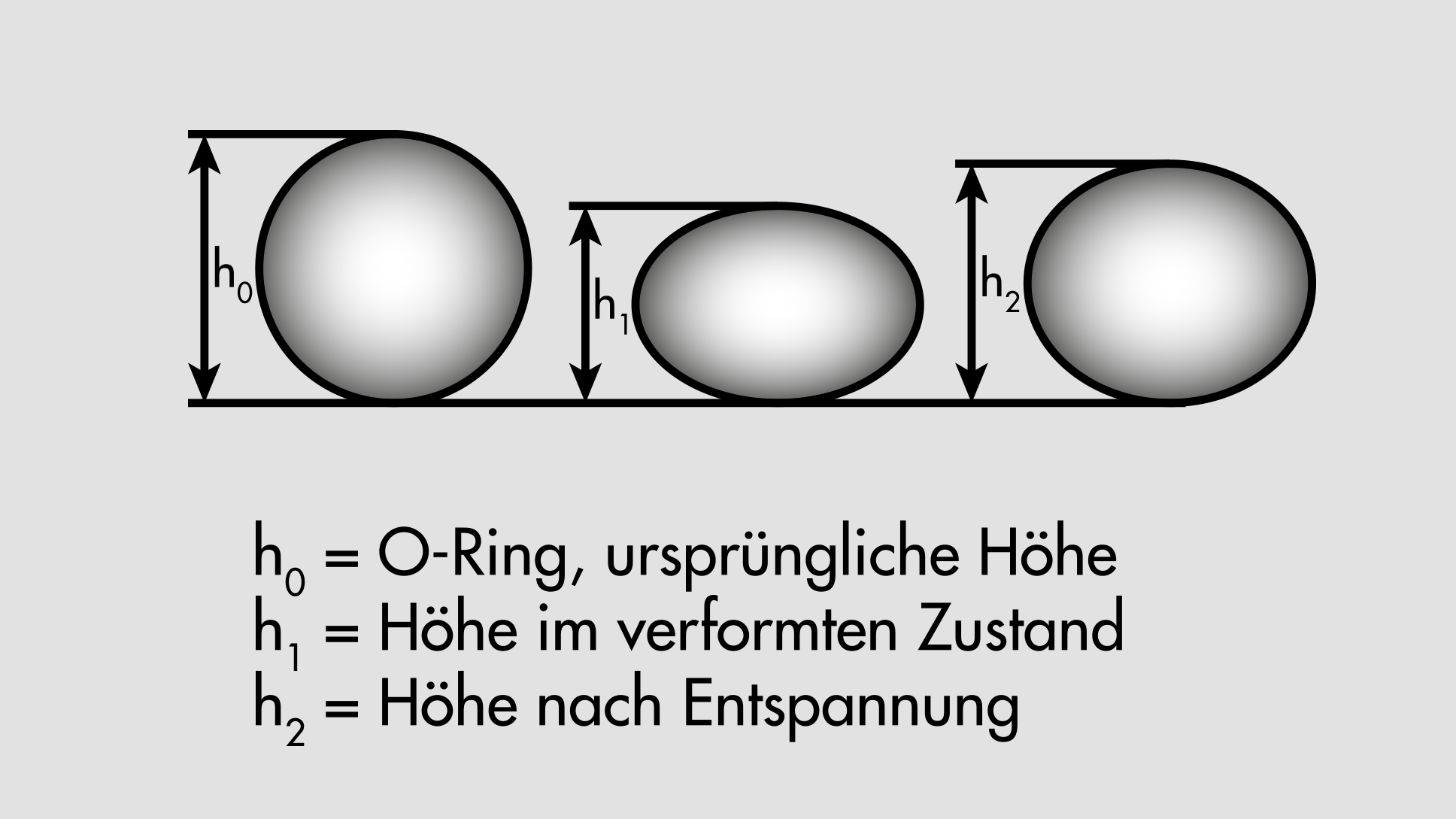

Compression set describes the amount of permanent deformation an elastomer retains after a defined, prolonged period of compression. Put simply, it indicates how well a rubber component returns to its original shape after being subjected to a compressive load—a key parameter for the long-term sealing performance of O-rings, profiles, and flat gaskets.

In the test setup, a test specimen (e.g., a cylinder or disc) is compressed to a fixed percentage of its original height—typically by 25%—and held at a constant deformation for a specific time and temperature. After the load is released, the recovery of the specimen is measured.

The compression set value is expressed as a percentage:

- 0% → The specimen recovers completely (the ideal, purely elastic case).

- 100% → The specimen remains entirely at the deformed height (no recovery).

In practice, realistic values fall somewhere in between depending on the material, temperature, and test duration; the lower the value, the better the elastomer's recovery capability.

Test Conditions and Standards

Compression set is determined according to standardised test procedures, such as:

- Solid rubber / elastomers: DIN ISO 815-1 / -2

- Flexible cellular materials (foams): DIN EN ISO 1856

Typical test conditions include:

- 72 h at room temperature

- 24 h at 70 °C

- Other combinations (e.g., 22 h at 100 °C or 150 °C) depending on requirements, material, and standard specifications.

Test duration and temperature are selected to reflect the intended application as realistically as possible—for example, continuous load in warm water, hot oil, or ambient air.

Factors Influencing Compression Set

The compression set of an elastomer depends on several factors, including:

- The type of elastomer (e.g. NBR, EPDM, VMQ, FKM, FFKM)

- The type of cross-linking (sulphur-cured vs. peroxide-cured)

- Fillers and additives in the rubber compound

- Test temperature and duration

- The degree of compression (deformation level)

An optimised material exhibits low compression set and high recovery even after long-term compressive stress and elevated temperatures.

Significance in Sealing Technology

In sealing technology, compression set is a key criterion for:

- O-rings in static sealing points

- Flat gaskets and profile seals subjected to permanent compression

- Profile and moulded seals in housings, covers, or flange connections

As operating time, temperature, and media exposure increase, the initial pre-load of a seal dissipates. A high compression set means the seal "springs back" less and the contact pressure drops—in extreme cases, leading to leakage. A low compression set is therefore crucial for a permanently tight connection, for example in hydraulic systems, process plants, or domestic appliances.

Synonyms / Related Terms: Compression set, permanent set under compression, residual deformation.

Contact