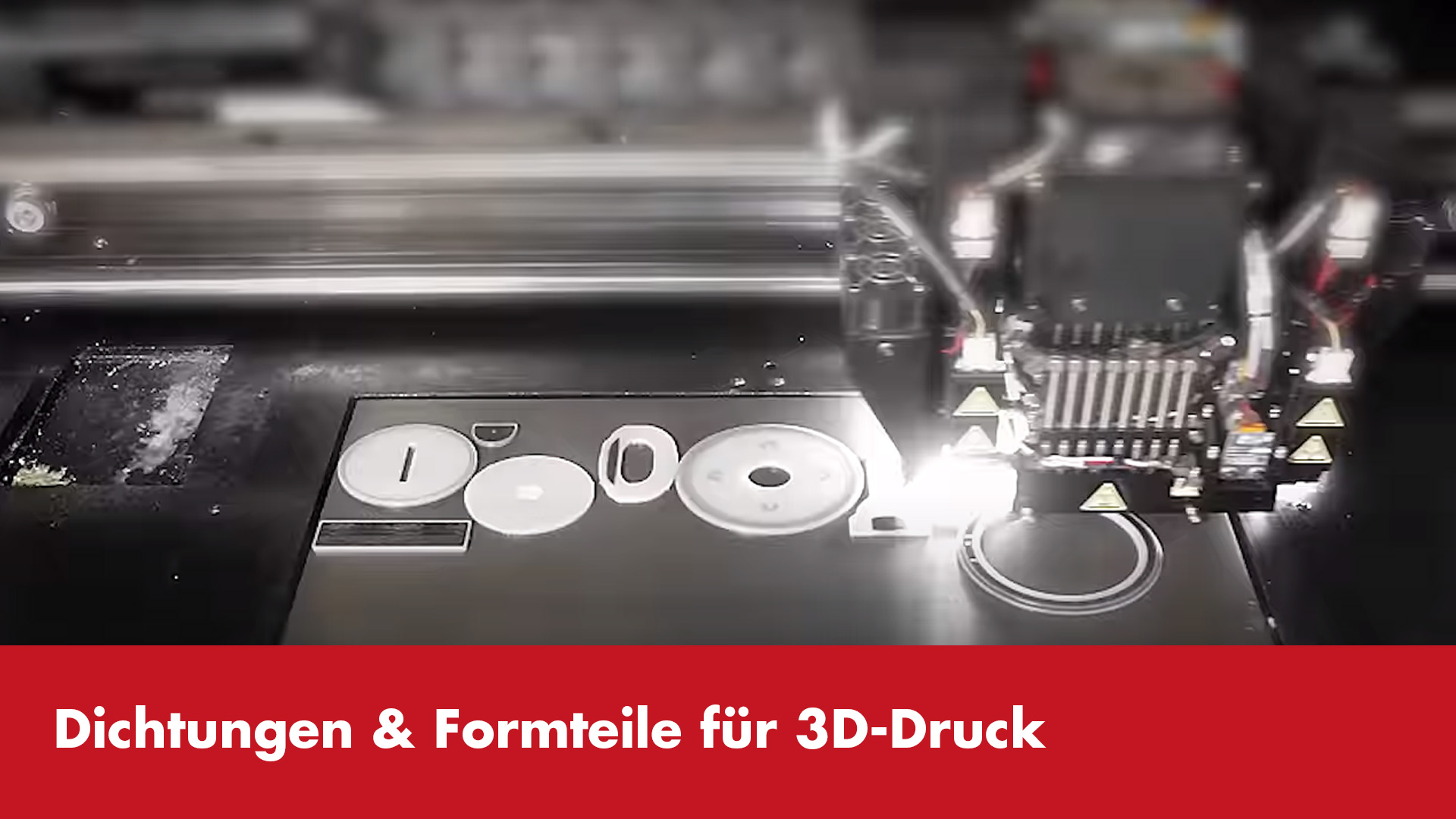

3D printing - production in the office

The 3D printing process

The 3D printing process

3D printing technology enables fast, affordable and extremely flexible prototype production without tools. Significant time and cost savings combined with a high degree of flexibility. Another advantage is that adjustments can be made very quickly during the process. Only after testing and selecting the appropriate prototype are the initial samples produced from series tools. The manufacturing process works in a similar way to an inkjet printer - but the results are not flat but three-dimensional.

- Fine details possible by applying wafer-thin material layers of 16 µm for wall thicknesses of up to 0.6 mm

- High image accuracy of e.g. material designations, date clocks, nest markings

- Smooth surfaces (also suitable for subsequent painting)

- Geometries at risk of deformation remain dimensionally stable (hose sections, lip geometries, etc.)

- Hard/soft combinations adhere firmly to each other

- Different Shore hardnesses of the base materials can be combined with each other and mixed digitally

- Dimensional tolerances of 0.1 mm for most models, generally up to 0.3 mm can be maintained

- Wide range of materials from transparent to opaque, from soft and flexible to hard and rigid

Three-dimensional prototypes made from different materials - an enormous time and cost saving

KREMER uses the 3D prototype printing process to produce detailed prototypes, including those consisting of several components, with different hardening rates in a single work step. The basis is the CAD volume model. The relevant components are assigned material property profiles (e.g. Shore A or D hardness). Different areas/parts can be taken into account for each volume model. This technology can be used to produce firmly bonded hard-soft joints, i.e. composite materials, in a single operation.

In addition to 3D printing, we can also offer other prototyping processes for the production of near-series samples.

Figures - Data - Facts

Molded parts/injection molded parts division (as at 2020)

Number of molded parts delivered in 2020

Realized drawing parts

Number of active customers in 2020

Sales share of largest customer in %

Application examples for 3D printing

A cable grommet is not a spectacular or complicated part in itself, but rather a promising new way of prototyping and the specific product requirements placed on the grommet.

The prototypes were manufactured using a technology that allows three-dimensional models to be produced from several materials and with different physical properties without the need to produce a prototype tool. An enormous time and cost saving.

In a single work step, sample parts can be created within a few days from the 3D CAD data, which, like the end products, can be made of different hard or soft materials. This allows, for example, buckling behavior and mountability (and functional tests to a limited extent) to be carried out at a very early stage of product development. Only after the suitable prototype had been adapted and tested were the initial samples produced from series tools.

A pre-assembled cable is to be fitted with a cable grommet and mounted together in a die-cast aluminum housing. The grommet is not pressed into the seat by a housing cover, but by a sealing cord from above.

It was defined from the outset that the connection elements of the cable would not fit through the hole; the grommet therefore had to be slotted.

This task in turn conflicted with the requirement to seal the housing against splash water. The difficulty lay in dimensioning the slotted grommet precisely so that all the resulting forces would exert sufficient compression against the housing wall and the cable, thus preventing deformation of the slotted cable grommet.

A standard cable grommet was therefore not an alternative. A tightrope walk that placed high demands on development and technology.

The pleated tube of the protective cap should be able to be bent upwards by 90° to its original position. Our customer had a stereolithography part produced for demonstration purposes in order to explain how the protective cap works.

KREMER produced a printed prototype from 60 Shore A soft material based on the CAD data provided.

In contrast to the stereolithography part, our prototype immediately showed that the number of folds would not be sufficient to allow the 90° bend to be made without colliding with the folds.

At KREMER's suggestion, two additional folds were added to the design of the protective cap. The connection dimensions remained unchanged. Prototypes were produced again with the corrected data set, which met our customer's expectations and formed the basis for the series parts.

The softness and flexibility of the material and the true-to-shape reproduction of the geometry were convincing in this part.

The rubber-elastic component is to be manufactured from a thermoplastic elastomer (TPE for short), the bearing ball as a hard component from a PA-GK 30 in a classic rotating 2-component mold. The rubber-elastic component serves as bend protection.

During the design phase, the buckling behavior of the elastic cable grommet was considered critical. A cable grommet that was too stiff would hinder the craftsman when operating the machine tool, while a grommet that was too soft would cause the current-carrying cable to fatigue too early.

Despite sufficient experience with the soft PVC anti-kink grommets supplied by us, the geometry could not be transferred to the new type of ball cable grommet. Instead, prototypes were to provide information on the functional design of the component.

Thanks to the printed prototypes, the kink susceptibility of the later series parts could be predicted very well. The necessary wall thickness corrections only had to be made on the CAD computer and the optimized data set used as the basis for series tool construction.

The comparison of the prototypes with the series parts was convincing: the potential savings of around EUR 5,000 compared to the costs of a conventional pilot sample tool were ultimately also convincing.

A small dimensional change to the aluminum extrusion profile led to unexpected installation difficulties for the EPDM glass support profile supplied to a conservatory manufacturer. KREMER was asked to ensure problem-free installation and stability by specifically adapting the base and clamping area of the glass support profile to the aluminum profile. The biggest problem: time pressure.

In this case, we adapted the CAD data set of the glass support profile and produced a 20 cm long and 60 Shore A soft profile section using the prototype printing process. This allowed us to analyze the mountability and functionality of the tolerance-compensating base and clamping area.

The results were available just three days after correcting the CAD data. The knowledge gained from testing the prototype could be used to build the extrusion tool. The printed prototypes accelerated the result. Speed was clearly the focus of our customer.

Contact